Galveston Island endures strong winds and hurricanes, so the houses are built on pilings; when the wind blows they flex a bit. Reasoning that this flexing would crack any tile work that I put on the walls of my house, I thought I was smart to install one-piece fiberglass tub/ shower enclosures in my two bathrooms.

I like a shower or tub floor to feel solid, so before setting the tubs, I placed 10 gallons of mortar under each one for complete bearing. Problem was, the enclosures had voids between the floor of the bathtub and the chopped fiberglass base. I could feel the voids flex as I stood in the tub, and soon the floors began to crack. Rather than replace the tubs, I came up with another solution.

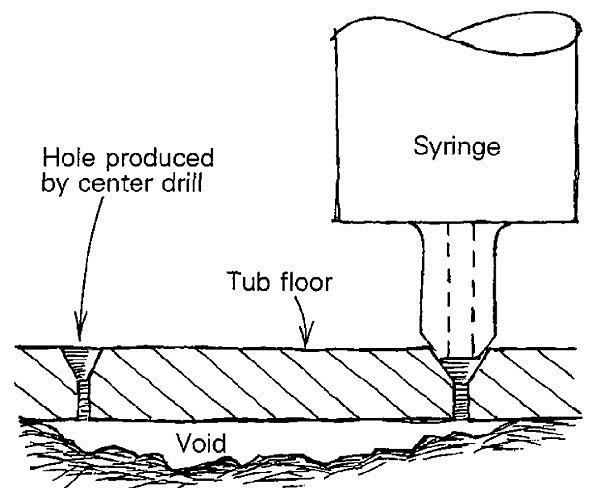

First I cleaned and waxed the tub floors with car wax. Next I used a center drill to bore holes at each end of each void in the tub floors, as shown in the drawing. Center drills combine a countersink and a drill bit and are available for a few dollars at any machine tool supplier. Then I used a syringe with the needle removed to inject fiberglass resin into one hole until it emerged from the adjacent hole. After wiping up the excess, I put a couple of drops of white-pigmented resin from my local boat supply atop the holes. Then to avoid any sanding, I covered each hole with a postage stampsize piece of wax paper. After the resin hardened, I pulled away the wax paper. The excess resin flaked away easily because the car wax prevented it from bonding to the tub bottoms, and the wax paper left behind a smooth surface. The fix took just an hour and a half.

Will Rainey, Galveston, TX