I had to restore an old double-hung window that measured 4 ft. by 6 ft., but only one of the two sash weights remained in its pocket. To make the window operational again, I’d have to come up with another sash weight. Not having a salvage yard nearby, I resolved to make my own weight.

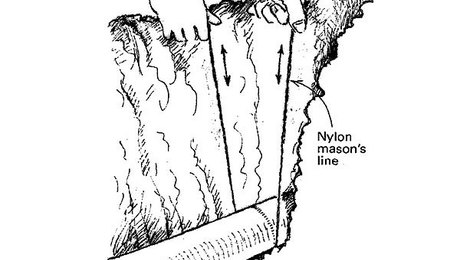

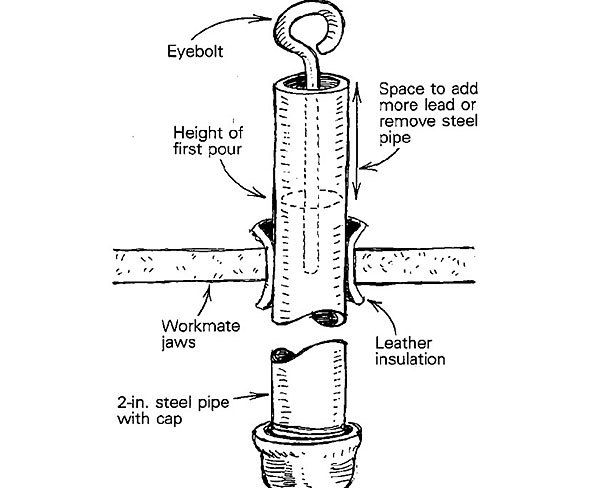

I had a 2-ft. length of 2-in. pipe on hand. As shown in the drawing, I capped one end of it and clamped it upright in the jaws of my Workmate. After figuring the difference in weight between the pipe and the original sash weight, I got out some old lead pipe to make up the difference. Wearing gloves, goggles and a respirator, I melted the lead in a plumber’s crucible and carefully poured it into my steel pipe. I did this outdoors, and protected the area under the pipe with some firebrick to prevent any spills from causing a fire. Once the lead was within a few inches from the top of the pipe, 1 inserted a 6-in. eyebolt and held it steady until the molten lead cooled enough to set up. The two weights ended up weighing virtually the same amount, but if I’d needed to adjust the new one, I could have added a little more lead to the space at the top of the pipe, or removed some of the pipe to trim it down a bit.

Dave Marlow, Warrenton, VA