Summary: This article explores the problem of building on very soft soil that will not support conventional footings and foundations. The author describes a system of concrete or wood pilings and steel-reinforced concrete grade beams to support the weight of a house. A sidebar warns against soupy concrete and improperly placed rebar.

Once in a while you dig a foundation footing and find the soil getting softer instead of harder the deeper you go. If by digging a few extra feet you can reach solid bearing, then the easiest and least expensive solution is to place your footings at that depth. But if the soft soil continues for several feet or more, better alternatives exist. One alternative is a steel-reinforced grade beam supported by some form of concrete or woodpiles.

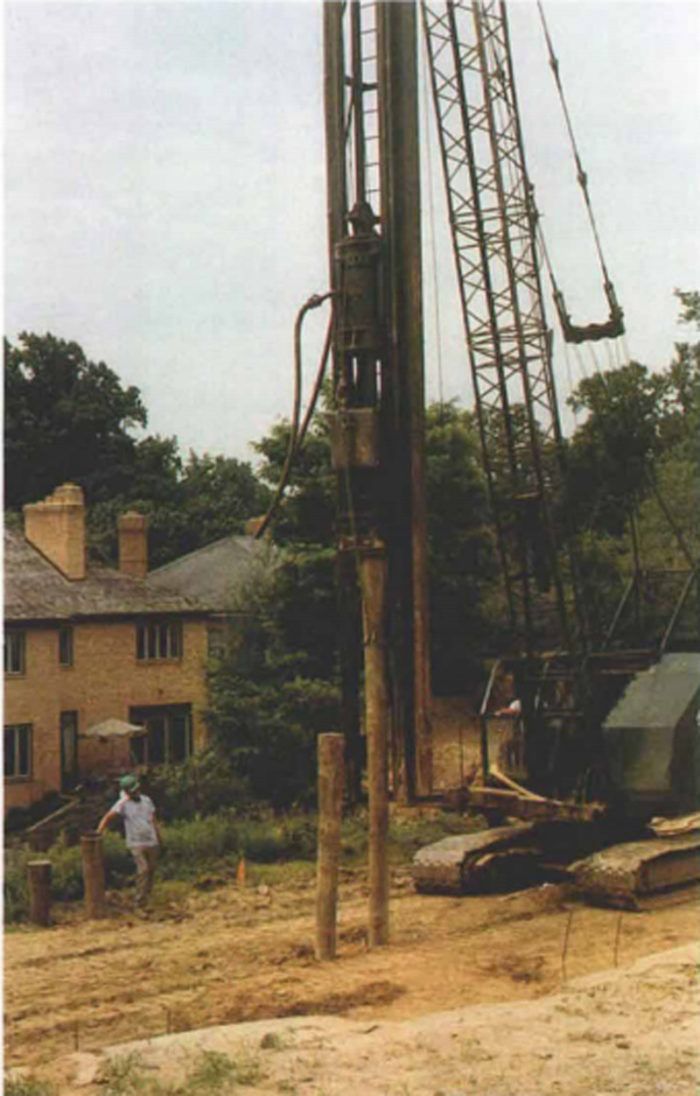

Concrete or wood? -— Concrete piles are usually placed into deep holes that have been excavated with a large auger (like the machine that’s used to install utility poles). In very soft soils, drilled holes often collapse before being filled and thus need to be lined with a hollow steel pipe called a casing. The casing may be left in place after being filled, or removed during concrete placement (whether it’s left or removed will depend on variables such as the character of the soil and the cost of the steel). A modification of this method eliminates the need for a casing. It consists of a special auger that injects concrete into the hole while simultaneously withdrawing from it.

Wood piles are usually driven in place witha pile driver, a technique that’s especially useful in fill soils that don’t contain stumps and rocks. Wood piles are driven down to a “refusal” depth. Refusal simply means that the pile won’t go any deeper, even though the pile driver keeps on hammering it. The approximate refusal depth can be accurately estimated using formulas that consider, among other factors, the power of the driver and the resistance of the soil. In general, driven piles have twice the bearing capacity of drilled piles. Not only do their ends bear on underlying soil or rock, but their sides also develop friction with the surrounding soil.

Coping with soft fill —- This case involved three adjacent lots in a draw (a small ravine). Two of the lots had been filled with up to 20ft. of spoil—dirt that had been excavated and removed from another construction site. The spoil had been trucked in about 20 years earlier and dumped without being compacted. While the fill had naturally consolidated over time, it was still too weak to support the very large, two-story homes that were planned for this site.

Although the underlying soil was probably strong enough to support the houses, it was much too far below the surface. A hole deep enough for two full-height basements would have been needed for conventional footings (such information can be gotten from test pits or borings, or by checking a topographic map that dates from before the fill was brought in). Construction feasibility and cost led the builder to choose treated woodpiles and to span the distance be-tween them with grade beams that doubled as wall footings.

Click the View PDF button below for photos and more detail.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Original Speed Square

100-ft. Tape Measure

Plate Level