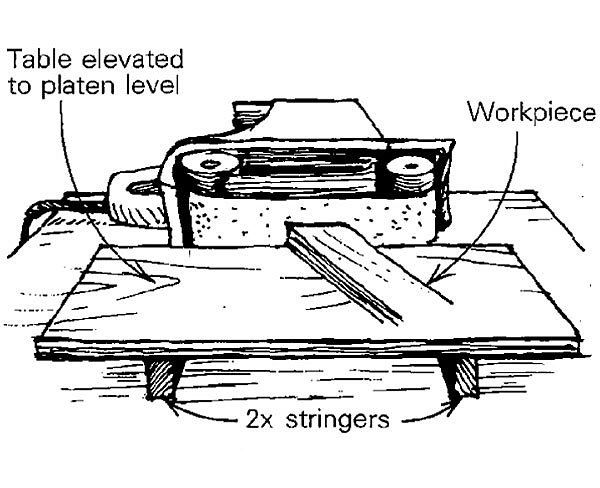

A finish carpenter doing meticulous, stain-grade trimwork can make good use of a stationary sander. It’s just the tool for taking off minute amounts of end grain in the quest for the perfect fit. Unfortunately, a stationary sander is too cumbersome to lug around the job site, so we’ve cooked up a dandy little substitute. As seen in the drawing, we’ve made a cradle that holds a belt sander on its side.

The bottom of the drawing shows the two vertical blocks that surround the handle and the fan/motor housing. A notch in one of the blocks accommodates the handle. We carefully fit the blocks, so we don’t even need a clamp to hold the sander in place during operation.

The upper part of the drawing shows the sanding table, which is glued to a pair of 2x stringers. This raises the table to the level of the sander’s platen. The stringers are in turn screwed to the base of the jig. To use all the areas of the belt, we put additional boards on the sanding table to act as spacers. We square the tool to the table with shims of scrap wedged under the sander. A more sophisticated version of this would include a pivoting table that could be tilted into square with the platen.

Sven Hanson, Albuquerque, NM