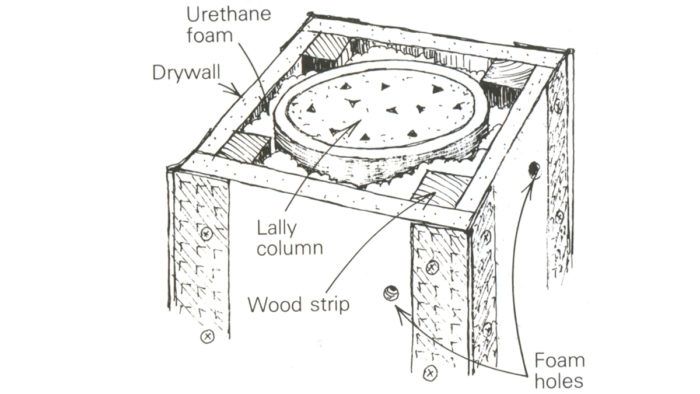

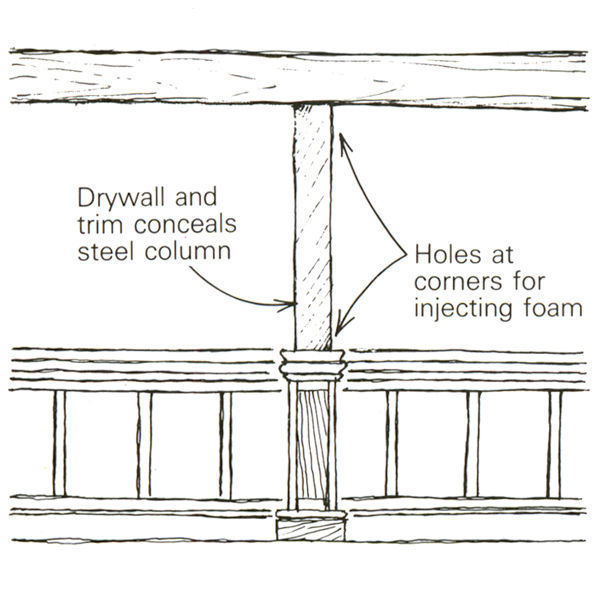

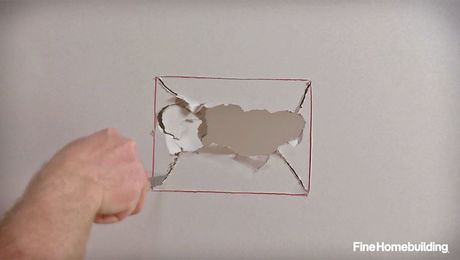

First, I boxed the columns with drywall. At the corners of the boxes, I screwed the drywall to straight-grain pieces of pine, ripped into 3/4-in. by 3/4-in. strips. The pine rippings reinforced the drywall corners from the inside. Then I applied the metal corner bead, again using screws to keep from banging the boxes apart. The problem then became how to secure the drywall boxes to the columns. As shown in the drawing, I drilled small holes next to each corner of the boxes at three elevations: near the top; 40 in. above the floor; and at the bottom. Next I poked the nozzle of a urethane foam can through each hole, depositing a generous dose of the expanding foam at each comer. The foam is very sticky, and it pretty much stays where you put it so I didn’t have to fill the entire box. A couple of hours later the foam was hard, and the boxes were surprisingly sturdy. Trimmed out with chair rail, wainscot and base, the columns (and the room) look great.

Edited and Illustrated by Charles Miller

From Fine Homebuilding #72

View Comments

Never heard of a lally column. And I'm a building inspector & plans examiner :-)

^^Obviously he is talking about the telepost...

http://www.lally-column.com

A Lally column is a round thin walled structural steel column oriented vertically to provide support to beams or timbers stretching over long spans. The steel shell of a Lally column is filled with concrete, which carries a share of the compression load, and helps prevent local buckling of the shell. The advantage of a Lally column over conventional structural steel is the ability to cut it to length on a construction site with simple hand tools such as a plumber’s pipe cutter or a reciprocating saw. Lally columns are generally not as strong or durable as conventional structural steel columns. The term "lally column" is sometimes incorrectly used in reference to other types of prefabricated steel columns.

The Lally column is named after a U. S. inventor, John Lally, who owned a construction company that started production of these columns in the late 19th century. He resided in Waltham, Massachusetts and Boston during the period 1898–1907. He was issued four U. S. Patents on composite columns: #614729, #869869, #901453,and #905888. Pat. #869869 was assigned to the U. S. Column Company of Cambridge, MA.

Early Lally columns were made with structural steel, "standard" pipes, with wall thicknesses slightly less than 1/4". Modern Lally columns are typically made with 16 GA (approx. 0.06") shells. Modern Lallies are therefore much lower in strength than the older ones (typically less than half the strength), and are also much more subject to damage by corrosion in moist environments. Modern Lally columns are primarily intended as somewhat stronger and more durable substitutes for wood posts in light-frame wood construction, although they are sometimes also used with steel beams.