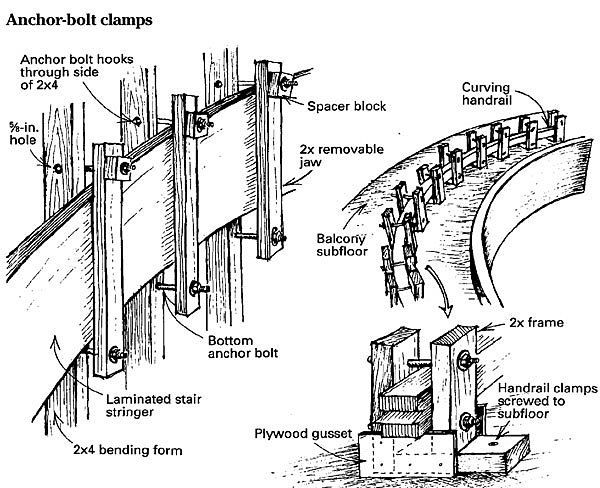

For almost a decade, I’ve concentrated exclusively on building stairs and handrails. Last year, I built three circular stairs with a diameter of 18 ft. Given the size of the stairs and the logistical nightmare of moving one from shop to job site, it made sense to build them on site. But when I began the first one, I came up against the problem of clamps. I figured I needed about 100 clamps for a curved stair project. Conventional C-clamps were too slow to install and tighten, too valuable to leave on a job site and too heavy to lug around. In searching for an alternative, I turned to anchor bolts. As shown in the drawing, I devised two kinds of inexpensive, site-built clamps that use 1/2-in. anchor bolts and 2x framing lumber. Around here, anchor bolts cost about 30 cents apiece, and I can fit all I need for a job in a 5-gal. bucket.

To laminate a stringer, I start by laying out the plan of the stair on the subfloor. Then I make a bending-form by securing 2x4s to the layout lines. As shown in the drawing, the 2x4s become part of the clamp. The top of each removable jaw is secured to its 2×4 with a 6-in. anchor bolt. The bolt’s hook fits through a 5/8-in. hole in the side of the 2×4, and a spacer block of a suitable thickness takes up the unthreaded portion of the bolt. The bottom of the jaw is secured to the form by an 8-in. anchor bolt that runs through the 2×4. In use, I insert the top bolt first, snug it enough to keep the assembly together and then run the bottom bolt through. I use an electric impact-wrench with a deep socket to tighten and remove the nuts quickly.

For handrails, I use a series of clamp brackets, as shown in the drawing. Here, they are screwed to a balcony subfloor to laminate a simple curved handrail, but they can also be affixed to stair treads to laminate spiral handrails.

Robert J. Dick, Lovettsville, VA