Making Plastic-Laminate Countertops

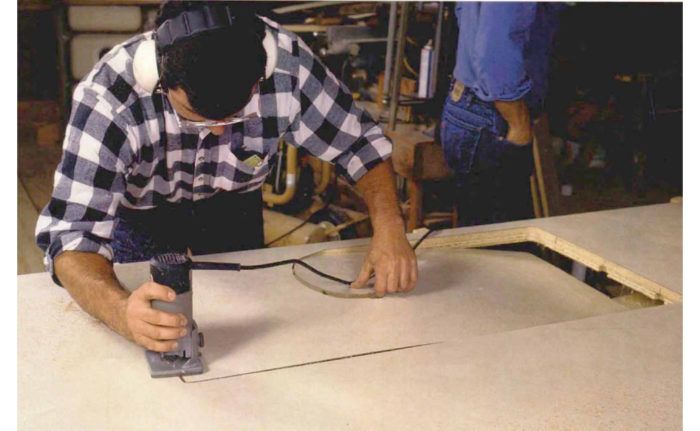

Cutting shears and spray adhesive are among the tricks that make the job easier.

Synopsis: An experienced kitchen contractor offers a step-by-step guide to fabricating countertops from plastic laminate, covering tools, techniques, and materials.

As a carpenter’s helper I learned the basics of working with plastic laminate 12 years ago. Since then I’ve fabricated more countertops than I can remember. Over the years I’ve witnessed a lot of mistakes and have made a few of my own. But there was a lesson in every error, and I’ve learned my lessons well. The tools and the techniques I’ll describe in this article make it easier and less frustrating to fabricate professional-quality countertops.

It’s not all Formica

Among the general public, all plastic laminate is commonly referred to by the brand name Formica. In fact, many customers don’t understand what I’m talking about unless I use the phrase “Formica countertop.” The confusion is understandable considering that the first plastic laminate was, indeed, Formica, but now there are other manufacturers.

Although most of my tops are done using Wilsonart laminate, because it happens to be the most readily available brand in my area, there is no difference between working with one brand or another.

Plastic laminate is made by bonding multiple layers of resin-impregnated kraft paper under heat and high pressure. The sandwich is topped off with a colorful layer of melamine.

Several manufacturers also produce a solid-color, or solid-core, laminate. This product is uniformly colored throughout its composition, so the dark band that shows up on the edge seams of standard laminate is eliminated. Another solid-core selling point is its ability to hide scratches that would show up on standard laminate.

I seldom use solid-core laminate, though. It’s more expensive, comes in fewer styles and, frankly, my customers don’t find the dark seam line unsightly; they expect it on a laminate counter. If you use solid-core laminate, you should know that it’s worked like regular laminate, but it’s more brittle. Use extra care when handling it, especially while cutting and routing.

Aside from the myriad choices of colors and patterns available, there are also different types of laminate, such as fire rated and chemical resistant. But if you go to your local lumberyard and order a sheet of, say, Erin Glenn #4627-8, the salespeople are going to assume you want the standard, general-purpose laminate, which is what I use on virtually every residential and light-commercial countertop I make.

Sheets of plastic laminate come in nominal widths of 30 in., 36 in., 48 in. and 60 in. Nominal lengths are 72 in., 96 in., 120 in. and 144 in. The actual sheets measure 1 in. larger in width and length. Some manufacturers also offer 1¾-in. by 12-ft, strips of laminate for edgebanding.

For more photos and details, click the View PDF button below:

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Plate Level

Anchor Bolt Marker