Hand Planes for Trim Carpentry

Tuned and adjusted right, these planes will save time and improve your work.

Synopsis: The author discusses the variety of hand planes that are used in trim carpentry, including block planes, rabbet planes, and mortising planes. Sidebars explain how to make a shooting board to adjust miters and how to sharpen plane blades.

More than 100 different wood and metal hand planes are described in R. A. Salaman’s book Dictionary of Woodworking Tools: c. 1700- 1970 (published by The Taunton Press, Inc.). Store-bought or handmade, many of these clever devices were once indispensable to builders. Before the advent of power planes and routers, a carpenter’s repertoire might include assorted bench planes for preparing and smoothing wood stock; molding planes for shaping everything from stair nosings to door casings; and various contraptions for plowing dadoes, grooves, and rabbets. A specialized carpenter might even own a compass plane for cutting convex or concave curves and a “galloping jack” plane for smoothing floorboards.

Nowadays, most of these planes are prized more by museum curators and tool collectors than by carpenters. But some types remain as vital on the job site as ever. As an architect/builder who specializes in trim carpentry, I use several kinds, primarily for fitting wood trim or casework against previously installed work, or wherever the use of a power plane or a router is impractical. My favorites are the block plane, the shoulder plane, and the butt mortise plane. I also use an assortment of specialty planes (I made some myself) for cutting roundovers and chamfers.

Hand planes are available from woodworker’s suppliers, tool outfits, and some hardware stores and lumberyards. But don’t expect planes to make smooth cuts straight out of the box. Properly tuned and adjusted, though, they’ll cut wood like butter and sing while they work.

The block plane

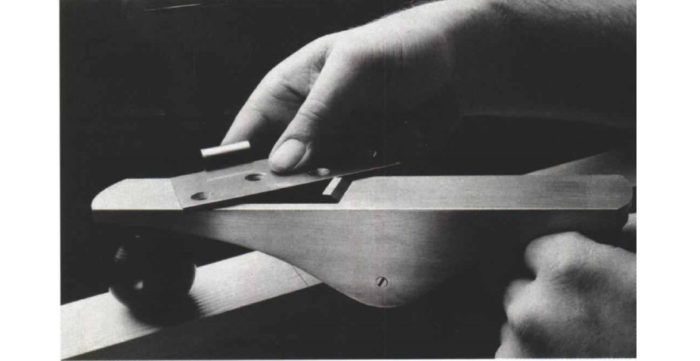

The typical metal block plane features an adjustable blade housed in a 6-in.- to 7-in.-long metal body. Mounted bevel-side up, the blade is clamped by a lever cap in two areas; against either one or two milled plateaus or a lateral adjustment lever at the top end of the blade, and against a narrow angled seat at the bottom end. The seat is directly behind the throat (the opening in the sole of the plane through which the blade projects). Depth of cut is controlled by turning a knurled nut or knob at the back of the plane.

Unlike its larger siblings—the jointer plane, the jack plane, and the smoothing plane—the block plane is designed for one-handed use and will fit into most tool pouches. These attributes make it the plane of choice for most carpenters. I use mine for trimming miters, fine-tuning the fit of passage doors and flush-mounted cabinet doors, cleaning up jigsaw cuts, fitting cabinets to walls, flush-trimming screw plugs, planing door jambs flush with adjacent walls before installing casings, and plenty of other routine tasks.

For more photos and details, click the View PDF button below:

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Paslode Cordless Finish Nailer (IM250A)

Milwaukee Cordless Tablesaw (2736)

Makita Top-Handle Jigsaw (4350FCt)