Q:

I am planning a second-story addition over my woodworking shop, and I don’t want any support post in my way on the first floor. I want to make box-beam floor joists. What size should I make the box beams to span the 19-ft. width of the addition?

Gary McClain, Darden, TN

A:

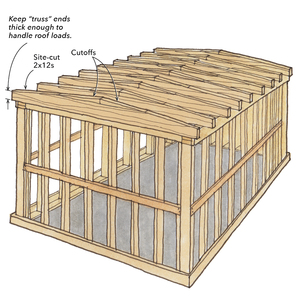

Christopher F. DeBlois, a structural engineer in Atlanta, Georgia, replies: A 19-ft. span carrying residential loads (10 lb. per sq. ft. dead load plus 40 lb. per sq. ft. live load) does seem to call for unusual framing. My first thoughts ran to wood I-beams, laminated veneer lumber or parallelchord wood floor trusses. But it turns out that there is no need for your box beams or for any of these approaches. In fact, ordinary #2 Southern yellow pine 2x12s, with a maximum moisture content of 19% and spaced 16 in. o. c., have plenty of strength to span 19 ft. (You should check this, of course, against your local codes.)

My primary concern with 2x12s at 16 in. o. c. is not their load capacity but their deflection and vibration behavior. Strength considerations limit this system to a 21-ft. span, but for a maximum deflection under live loads of 1/360 of the span length (about 5/8 in.), these joists can span only 19 ft. 11 in. To increase the stiffness of the system and thereby reduce both deflection and vibration, follow the guidelines of the American Plywood Association (APA, P. O. Box 11700, Tacoma, Wash. 98411-0700; 206-565-6600) for its “Glued-Floor System.” The system is described in the APA’s publication Design/Construction Guide: Residential & Commercial ($2).

The glued-floor system doesn’t increase the strength of your joists; the 2x12s still do all of the work. But it will increase the stiffness. Using subfloor panels rated 16 in. o. c. or 20 in. o. c., the allowable span jumps to 20 ft. 11 in. That extra distance may not sound like much, but it represents a 25% bonus in the floor stiffness.

The additional work involved to comply with the APA’s recommendations is not all that great and yields a large benefit. You already need the 2x12s to span the 19 ft., and you’re going to need a subfloor, so the only extra costs are for the correct glue and the labor involved in gluing the floor properly. The system requires all joints in the subfloor panels to be glued with a glue that conforms to APA Specification AFG-01. If the label on a container of glue states that it conforms to this specification, then it is acceptable for use with the glued-floor system. Joints that run perpendicular to the joists must be either glued tongue-and-groove joints or square-edge-panel joints glued to blocking below.

The APA guide also discusses proper nailing. If your floor must also act as a horizontal diaphragm to handle wind or earthquake loads, more nailing may be required. Check with a structural engineer if there is any question.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Magoog Tall Stair Gauges

Stabila Classic Level Set

Guardian Fall Protection Pee Vee