Single-Setup Drawer Boxes

Set your fence and dado blade just once for this simple way to join drawer parts.

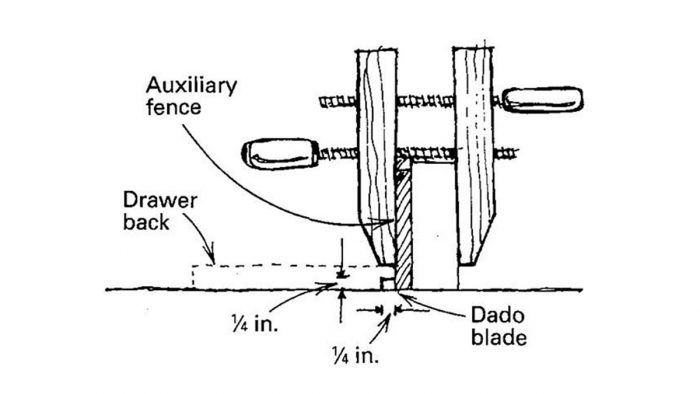

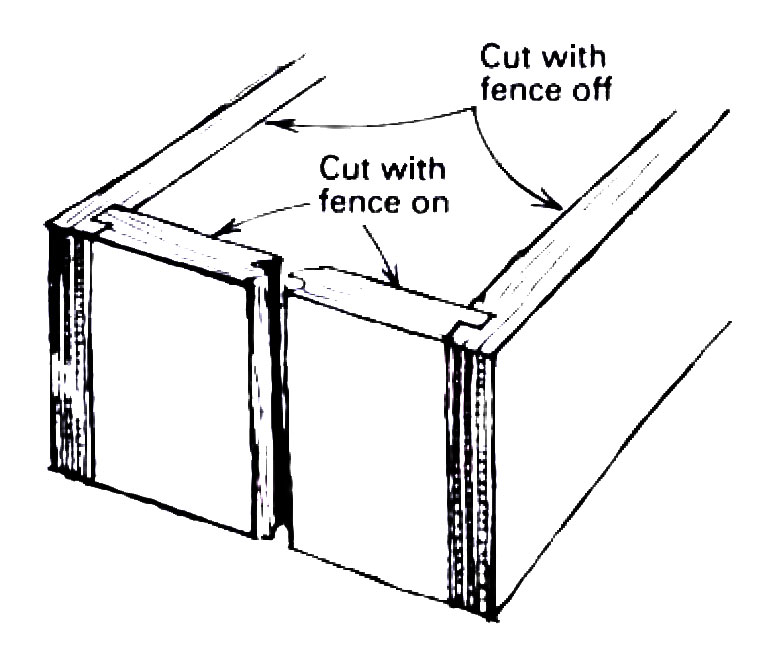

I make my drawer boxes out of 1/2-in. thick maple plywood joined at the corners with housed rabbet joints. And for the sake of efficiency, I fabricate all the parts on the table saw with a single dado-head setup and an auxiliary fence. The important dimension in setting up the saw to make the cuts is half the thickness of the plywood — 1/4 in. in this case. The dado blade is 1/4 in. wide. It is set 1/4 in. above the saw table, and the fence is positioned 1/4 in. away from the dado blade. The auxiliary fence is also 1/4 in. thick.

To use the setup, I begin with the auxiliary fence clamped in place. I cut the rabbets on the drawer fronts and backs, using wide pieces of plywood stock that have been cut to length but not to width. Then I remove the auxiliary fence and repeat the procedure for pieces of plywood cut to the correct length for the sides of the drawers. With the dadoes and the rabbets cut into large blanks, I can rip them down to the correct width for the drawers with the rabbets already plowed. This allows me to cut down the number of pieces passed over the dado blade.

By the way, if you set the clamps on the auxiliary fence at the right height, they will act as hold downs to keep the stock on the saw table as it passes over the dado head.

—Ross Fulmer, Kamuela, HI

Edited and illustrated by Charles Miller

From Fine Homebuilding #77

View Comments

This is actually 3 setups one set up with auxillary fence, another set up without the auxilary fence, and another set up for the width...

SeanLinster: Please read the tip and not just the heading. It's a "single dado-head setup". I would presume from your comment that you've never used a dado head and don't see the benefit of this tip. Dado heads do take a bit of time (and care) to set up.

I have used a similar setup for drawers, but instead of using an auxiliary fence, I stand the front and back stock against the fence, creating the "tenon" between the blade and the fence. Then I cut the side stock laying flat on the table. If I have ripped the stock to width ahead of time, I can also dado the bottom edge for the drawer bottom with the same setup, unless I am using undermount slides. More often than not, I run all this stock on the router table, so I can cut the plywood to length but not to width, cut all the end rabbets and dadoes on the router, rip widths on the table saw, then go back to the router to dado for bottoms.