Q:

What’s the easiest and least-expensive method of constructing a second-floor deck with minimal slope that also serves as a roof for a first-floor porch?

M. C. Ballard, Lumberton, MS

A:

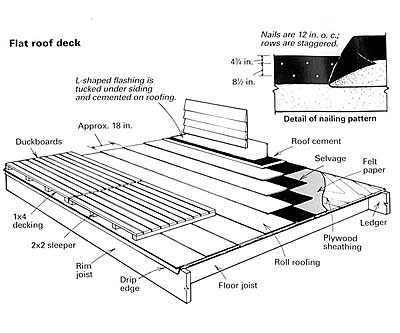

Contributing editor Scott McBride responds: The easiest and least-expensive way to roof over a flat, sheathed deck is to use double-coverage roll roofing. But first, the roof deck should be built with some pitch away from the house—at least 1/4 in. per ft. Manufacturers of roll roofing recommend at least 1 in. per ft. for double-coverage roll roofing, though I’ve seen dead-flat rolled roofs that remained tight for many years.

The roofing is 3 ft. wide by 36 ft. long and comes in rolls available in black or white. Other colors are tougher to come by. Courses of roll roofing overlap by about half the width of the sheet. The exposed half of the sheet is covered with granules, similar to those on asphalt threetab shingles. The other half of the sheet, called the selvage, has no granules. It gets nailed to the roof deck with two rows of nails. The first row is 4-3/4 in. from the top edge of the selvage; the second row is 8-1/2 in. below the first row. Nails are 12 in. o. c., and the rows are staggered. The selvage is then smeared with a thin, asphalt roof cement and covered by the next sheet. Sheets are normally laid out parallel to the eaves. The hardest thing about roll roofing is keeping the bloody roof cement from getting all over the place.

An underlayment of 15-lb. felt can be installed between the deck and the roll roofing. The felt cushions the roofing and gives an added layer of water protection. The felt also gives you something to cement the first course of roll roofing to.

At the juncture of the deck with the sidewall, you should install a wide, L-shaped metal flashing. One leg of the L gets cemented to the roll roofing, and the other leg extends up behind the siding. You’ll have to pull the siding nails or punch them through with a nail set to slip the flashing up behind the siding.

Unfortunately, the roll-roofing granules wear away quickly under foot traffic, so if the deck is to be used for more than an occasional sunbath, you’ll need to cover the surface with duckboards—small sections of wood decking that can be removed so that you can clean off the roof. This cleaning should be done once a year and more often if you have trees overhead.

Duckboards must be manageable—sections shouldn’t be more than 6 ft. by 6 ft. A serviceable duckboard can be made by screwing 1×4 decking to 2×2 sleepers. Leave about 1/4 in. between 1x4s. Redwood and cedar are ideal for the decking because they’re stable and lightweight. The sleepers should be pressure-treated yellow pine, which holds screws well. Use galvanized screws.

Sleepers should run parallel to the roof slope to permit drainage. They can be tapered to compensate for the roof pitch, creating a level walking surface, although tapering the sleepers complicates the fabrication. Sleepers can become welded to the asphalt in the roll roofing under heat and pressure. To prevent this, place a strip of aluminum flashing under each sleeper.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Peel & Stick Underlayment

Flashing and Joist Tape

Roof Jacks