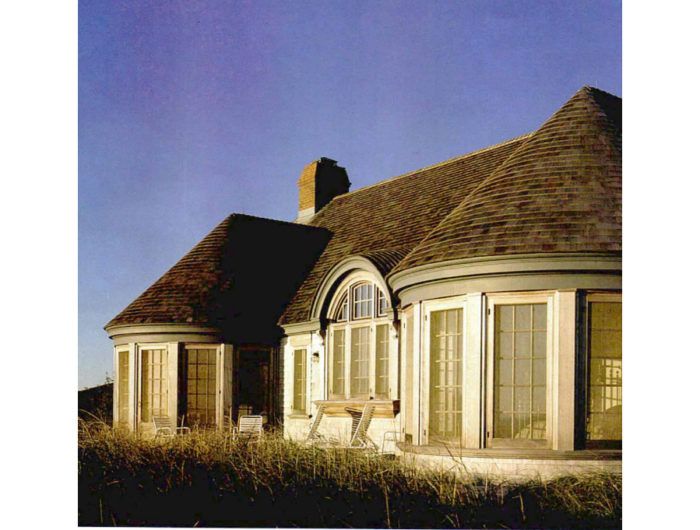

Classical Details in a Harsh Environment

Craftsmen build a coastal house to withstand hurricane winds, meticulous architects, and exacting clients.

Synopsis: This article describes construction of a richly detailed house on Cape Cod, paying special attention to techniques and materials that prevent damage from the weather in this demanding coastal climate.

The first time I visited the building site, I was humbled by Mother Nature. With my head bowed, and a site plan held tightly to my chest, I made my way against 45-mph onshore winds and walked to the easternmost edge of the property. When I looked up, squinting against the blowing sand, I was standing on the lip of a sand dune, about 80 ft. above the Atlantic Ocean. Even during the tail end of a Nor’easter, it was easy to see why the site had been selected as a place to build a house.

The views were breathtaking. The ferocity of the weather added to the drama of the site. This section of New England coastline is frequently buffeted by gales, and over the last decade, the beaches have taken the brunt of three hurricanes. In short, this was a location that would test the integrity of any building.

The people who owned the property wanted a house that would stand up to the weather while looking as if it had occupied the site for decades. They sought a style that would complement the land and reflect the most beautiful aspects of the area’s traditional architecture.

Having built houses for more than two decades, I have become a firm believer in the absolute importance of beginning a project with a complete set of plans. Good plans are not those found in plan books or in the back pages of home magazines.

The architect of the house, Allan Greenberg of Greenwich, Connecticut, is known for his adherence to the classical tradition. Given his reputation for strict attention to detail and the client’s demand for a beautifully crafted building, it should have come as no surprise to me when, prior to the commencement of the project, I received a 160-page project manual. A brief review of this volume, and I quickly learned that perfection would be the only acceptable standard. This was a job where cost took a position secondary to the quality of the work. The construction took almost two years and incorporated the skills of dozens of tradesmen, including 14 carpenters. A field architect from Greenberg’s office reviewed the project’s progress at least once a week. There were also two site inspections from representatives of the structural engineering firm.

Engineered to withstand 135-mph winds

Because the house occupies a site that would constantly test its structural integrity, it was engineered to withstand 135-mph winds. The specifications required many components not regularly incorporated in a house in this part of the country: glue-laminated beams, hurricane ties and hold-downs, special concrete requirements—including slump tests for all the transit mix delivered to the job—even the framing lumber was unusual.

For more photos and details, click the View PDF button below: