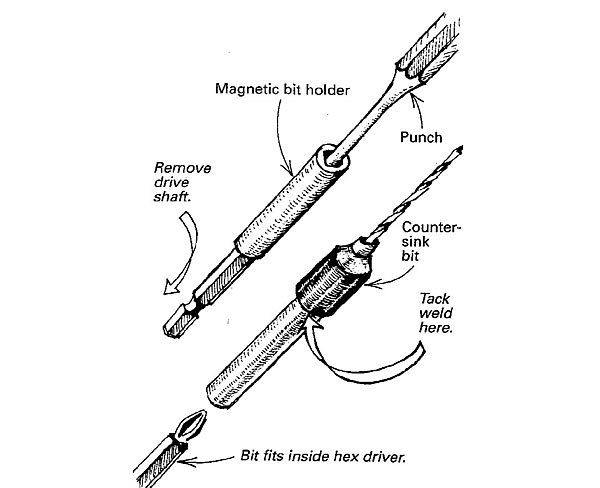

Bugle-head screws are easy to drive, but I’ve found they can split the work if I don’t drill a pilot hole that includes a countersink. However, changing back and forth from a countersinking drill bit to a Phillips bit is time-consuming. The drawing shows my solution.

Using a punch, I removed the drive shaft from a magnetic bit holder. That left me with a cylinder with a hexagonal hole down its middle. To one end of the cylinder I tack welded a countersink drill bit and ground the weld smooth. Now when I need to drill a pilot hole, I slip the open end of the cylinder over the hexagonal shaft of my Phillips bit. Hole drilled, I pull off the countersink and run the screw home without having to change bits.

Kevin Lane, Portland, OR