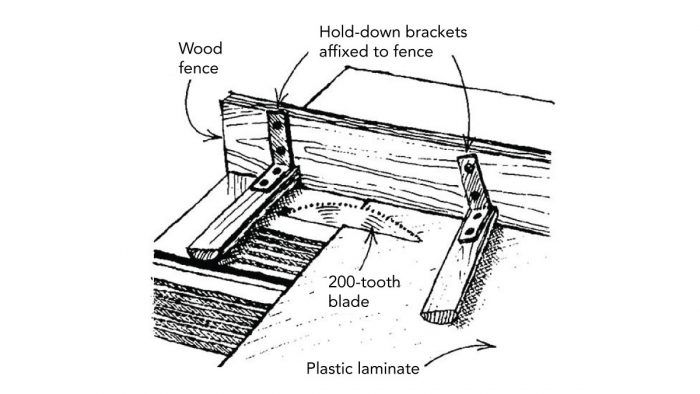

Whenever I have to make long, narrow strips of plastic laminate, I start by putting my portable saw on the floor. That way the floor can act as a huge saw table to support the floppy ends of the laminate as it’s passed over the blade. As shown in the drawing, I mounted a pair of wooden hold-downs on my saw’s fence to keep the laminate from riding up as it’s cut.

I wrapped the metal fence that came with the saw with a piece of 3/4-in. plywood. The plywood serves as a base for the screws that secure the hold-down brackets. And unlike the saw’s factory- issue fence, the bottom edge of my modified fence meets the saw table, which prevents the thin plastic from sliding under the fence.

This system works best when you’ve got two people to manage the unruly sheets. But I’ve also used the rig solo to rip narrow strips from a 4-ft. by 12-ft. sheet of plastic laminate.

—Byron Papa, Madison, AL

Edited and illustrated by Charles Miller

From Fine Homebuilding #88

View Comments

I would have used a larger piece of wood oriented parallel to the blade, and over the blade. Raise the blade to let it cut into the hold-down piece, hopefully somewhat centered in the hold-down piece but it doesn't matter as long as it extends past the blade front and back. Bevel the front edge of the hold-down block so that the laminate will start easily under the hold-down. By doing this, the laminate is held down on both sides of the blade, all the way from front to back. No lift-off between the hold-downs, no jamming against the back hold-down. Once it goes under, it stays under until it's past the blade. I'd hold the block in place with two pieces attached to the wood fence similar to what's shown, but attached to the bigger hold-down block.