Curved Baseboard Corners

Biscuit joinery and a simple jig solve a perplexing trim problem.

Synopsis: This short article describes a technique for making curved baseboard corners by milling stock on a shaper and assembling pieces with the help of a simple biscuit-joiner jig.

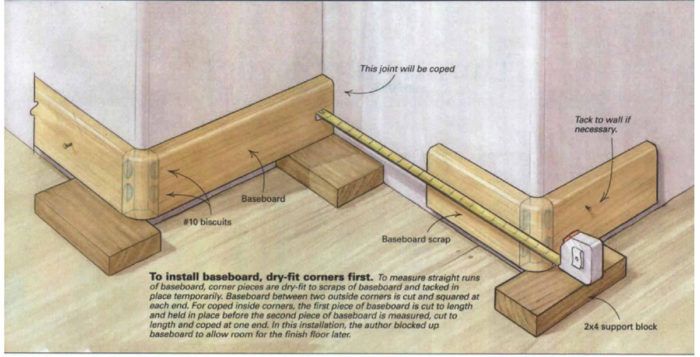

Thin-coat plaster is increasingly popular for interior walls in northern California where I work, but the variable textures and the bullnose corners of these walls can raise havoc when it’s time to apply trim. I discovered this a couple of years ago when the crew I was working on started to install baseboard in a house near Santa Rosa, California. Mitering the baseboard around the outside corners was out of the question. Square corners would look bad juxtaposed with the bullnose walls, and mitered corners would leave an awkward gap between the wall and the baseboard. Pondering paradigms led us to our current solution.

Our technique requires only a biscuit joiner, a simple jig, and rounded corner stock that we have run off at a local mill shop. The back of the rounded corner pieces are concave, so they fit snugly against the radius of the plaster walls at the corner. That eliminates the triangular gap that would result if the baseboard were mitered at 45°. In this house we butted the 1×6 maple baseboard into the rounded corner pieces, so the baseboard follows the wall cleanly, even if the comer isn’t exactly 90°.

It took trial and error to get the technique right. We realized that rounded corner stock was part of the answer; the trick was learning how to join the baseboard and the corner pieces together cleanly. We resolved the problem with biscuit joinery, using a jig we devised. The technique is fast and effective.

Corner pieces from a mill shop

The comer pieces were created with a single pass through a multiple-head molder, producing 10-ft.- and 12-ft.-long pieces that we cut to length on the job. Because the shop grinds knives for each job, it could easily make radiused corner pieces. You can also make the pieces yourself.

For baseboard that will be painted, grain direction in the corner pieces is irrelevant. That was the case on this job. But the mill shop we use also can produce corner pieces with the grain running horizontally, just like the base. That would be helpful if the trim were going to get stained, and the grain direction had to match.

Corner pieces first

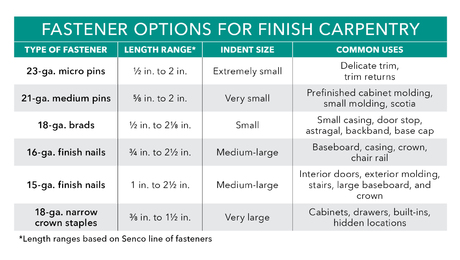

We have a three-step procedure for fitting baseboard, and we start with the corner pieces. After cutting the pieces to match the height of the baseboard, we put them in our jig and mark the locations for two #10 biscuits (biscuits come in three sizes, ranging from #0, the smallest, to #20, the largest). Using #10 biscuits with 1×6 baseboard means we can get two biscuits at each joint, and the slots aren’t deep enough to break through the face of the corner pieces. (We cut the biscuit slots in the baseboard later, after all of the pieces have been cut to length.)

For more drawings and details, click the View PDF button below: