Q:

While on a construction site, I came across a steel tool called a stair gauge, manufactured by the Eliason Stair Gauge Co. It appears that they are out of business. Do you know where I can find a similar tool?

Edward den-Haan, Westerville, OH

A:

Stephen Winchester, a carpenter and woodworker in Gilmanton, New Hampshire, replies: I use a device similar to the steel one you saw, but I made my own from wood scraps, so it didn’t cost me anything.

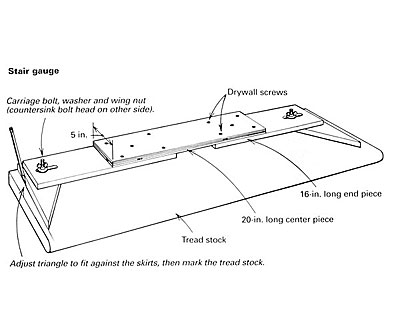

I started with three scraps of wood about 5 in. wide. Two of the pieces were 16 in. long; the third piece was 20 in. long. I cut a slot in the end of each 16-in. piece by boring two 7/16-in. holes 2 in. apart and connecting the holes with a jigsaw. Next I made two triangles from 3/4-in. skirt-board stock. They’re not quite right triangles; the corner angle is about 85°, allowing the triangles to fit into out-of-square corners. I counterbored and inserted a 3/8-in. carriage bolt in the center of each triangle. I put the triangles down with the bolt threads facing up. I set the 16-in. pieces down over the bolts and put on a flat washer and a wing nut. Finally I laid the 20-in. piece over both 16-in. pieces and fastened it with some drywall screws. One stair gauge, complete.

To use the gauge, I place it on the stringers, push the triangles tight to the risers and skirts and tighten the wing nuts. I remove the gauge, lay it on the tread stock and mark the ends. As long as I cut right on the lines, the tread should fit perfectly. In fact, the fit is so perfect that it’s a good idea to back-cut one end so that the tread slips into place more easily.

Because of the slots in the 16-in. pieces, the gauge adjusts 2 in. or 3 in. using the wing nuts. To change the length of the gauge, I remove the drywall screws and reposition the 20-in. piece.