Making Concrete Countertops

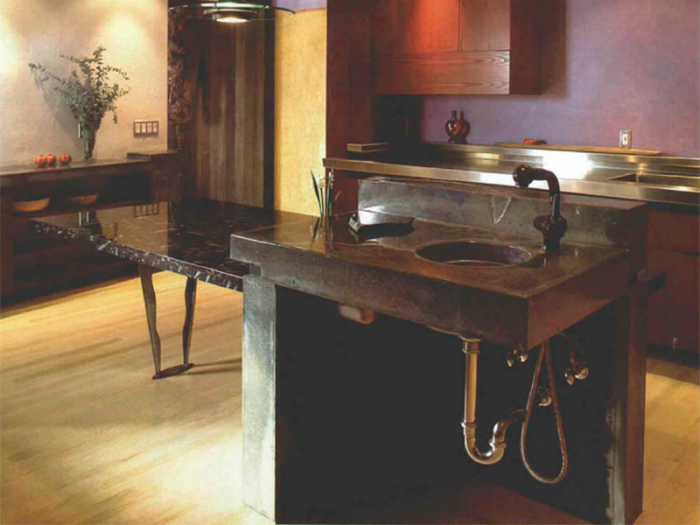

Solid, durable and attractive, an uncommon countertop can be cast from common materials.

Synopsis: Published well before the current craze for concrete countertops, this article explains how a furnituremaker and builder cast his kitchen counters in two sections and then installed the finished product.

I was in the last stages of building a house for John and Kathy Buckley when they decided on a concrete countertop for their kitchen. Ordinarily when clients start making last minute decisions like this, it can drive the builder to the aspirin jar. But I have to admit, my reaction was immediate and not even cautiously optimistic. I liked the idea.

John and Kathy considered marble and granite as a counter surface but felt it was ostentatious. Plastic laminate lacked pizzazz. But concrete had just the right mix of a stark industrial image, weathered outdoor coarseness and coloration, and a sense of solidity and strength.

I’ve used concrete in many projects, from foundations to flatwork. So I felt comfortable with the task of forming the counters. The part of the project that I wasn’t so sure about concerned the finishing of the counter to a surface that would be tough enough to withstand kitchen usage.

First, make test samples

Before beginning the actual counters, I made a series of 10-in. square by 2-in. thick concrete samples, using different finishing techniques on them. I used a magnesium float on some of the samples, which brought more cream to the surface. I steel troweled these samples, and they had a crackled look when they cured.

I let other samples cure without a steel-troweled finish. Then I sanded them with a belt sander and a random-orbit sander to reveal the pattern of sand and aggregate. I applied the finish I had chosen for the counter (more on that later) to the samples and had the Buckleys evaluate them. They chose the most uniformly gray of the steel-troweled batch, with a little aggregate showing from sanding for color and texture.

All three of us liked the somewhat honeycombed edges of the sample blocks. The edges were marked with the typical voids and cavities of poured concrete, where lumpy clusters of cement-coated pebbles reveal the rocky contents.

A two-piece countertop

Where to pour? That’s the dilemma facing anybody who’s making a concrete countertop. If you cast the top in place, you eliminate the hassle of moving around a heavy, cumbersome slab of concrete. But there are problems with that approach. In addition to dealing with the mess that accompanies any concrete pour, a countertop has to be etched with muriatic acid and then thoroughly rinsed before its finish can be applied. I didn’t want to introduce that wild card into the final stages of trimming out the Buckleys’ house.

For more photos and details on making concrete countertops, click the View PDF button below.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Anchor Bolt Marker

Plate Level

Smart String Line