An Exemplary Folding Workbench

Ingenuity, some scrap wood and $60 of hardware are all it took.

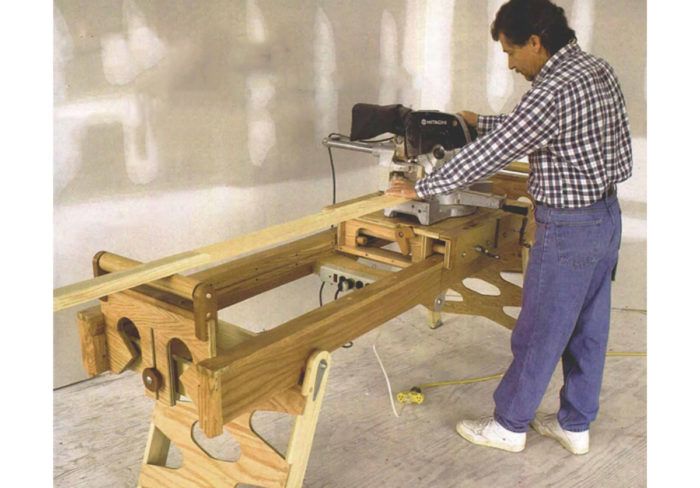

Synopsis: This is a description of an unusual and ingenious folding workbench devised by an architect turned finish carpenter. It handles a variety of tasks and folds down to 2 ft. by 4 ft. by 18 in. for easy transport.

If necessity is the mother of invention, then Kazimierz Pawlik might well be the father. He used scrap oak from a couple of his jobs and adapted common hardware available at Kmart to build a workbench as sturdy as a plow horse and as versatile as a Swiss army knife.

During the mid-’80s, Pawlik left his architectural practice in Poland and came to the United States. But he wasn’t licensed in this country, so he couldn’t practice architecture. Pawlik got a job as a carpenter’s helper near Bethlehem, Pa. After a couple of years, he started his own company specializing in finish work.

Pawlik and his crew work at incredible speed and to a high level of quality. They typically trim out a 3,000-sq. ft. house in three days. Pawlik’s ingenuity is evident in everything he does: the way he has outfitted his work van, the gauge he made to cut stair treads, the jig that enables him to install a prehung door in one minute.

But perhaps his most ingenious invention is the workbench he designed and built. He wanted a bench that was portable, sturdy and easily adaptable to diverse jobs.

The most remarkable aspect of Pawlik’s bench is that its multiple tasks are accomplished without any sort of Rube Goldberg-like gyrations. Everything operates simply and smoothly. The whole bench weighs about 50 lb. Metal parts are used where needed, but where wood will suffice, dovetails and butt joints account for the bench’s strength.

When folded up, the bench is small — 23 in. by 43½ in. by 17½ in. When unfolded, the bench becomes a multipurpose work surface 32 in. high and 85½ in. long.

A hinged frame and folding legs

The backbone of the bench is a 1×6 frame to which most of the components are attached. The frame folds in half on hinges made of oak knuckles and carriage-bolt pins. To keep the carriage bolts from spinning in their holes, Pawlik filed square the holes in large galvanized washers, which are riveted to the oak.

To keep the bench frame rigid, 1x3s are screwed along the top edges. At the hinge, where the two halves of the frame butt, keys cut into the subframe register the two halves of the frame when it is folded open, providing further lateral rigidity. Other keys cut into the 1x3s register the two halves of the frame when it is folded up.

The bench rests on two pairs of legs strengthened and kept from racking by plywood stretchers. Cutting out sections of the plywood reduced the weight of the stretchers without substantially diminishing their strength. The top edge of the plywood stretchers acts as a stop for the canted legs when they are unfolded.

For more photos, drawings, and details, click the View PDF button below:

View Comments

where can I buy the plans?

same question - where can I buy the plans or are they now the property of the Smithsonian Institute? : )

Sadly, Pawlik is no longer with us

A pity he's gone- we could use more architects who can hang and trim a door, using an elegant workbench they designed and built.