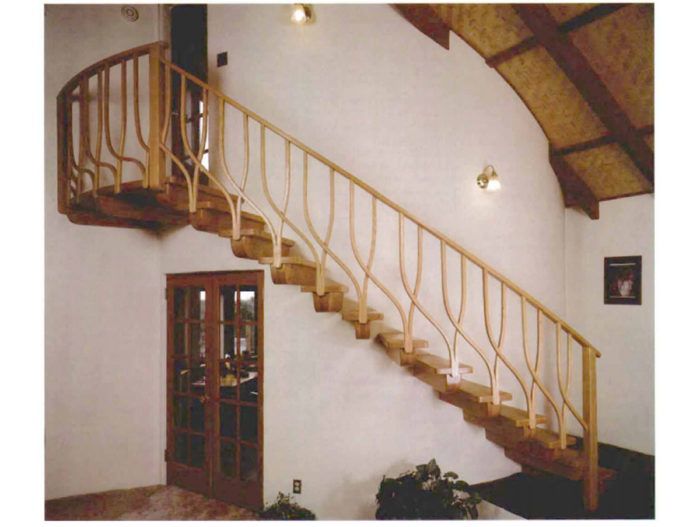

Synopsis: This article gives a short description of a cantilevered stairway in which hidden steel brackets do the work, an innovative alternative to a conventional staircase.

Curves make my heart sing. When I built my own house, one of the things I did was to frame a 16-ft.-diameter, two-story cylindrical room. The curving wall was a great place to locate the stairway. I had a picture of a curved adobe building with slabs of wood for stair treads cantilevered out through the wall. I wanted to build a similar stair, but the problem was how to capture the adobe-house stair’s light, suspended feeling, yet have it structurally sound and in compliance with the building code.

Steel solves the problem

I tried a whole bunch of wood-based designs, but the only one that worked involved extending the cantilevers through the other side of the wall, and that created space problems. Then, a friend suggested using steel to support the stair treads. Being primarily a woodworker, I had to be talked into it, but steel made for strong cantilevers that I could contain within the 2×6 wall.

I had a machinist make stair-support brackets from plate steel. Most of the brackets are two plates lapped and welded to form a T shape. The top of the T is fastened to the studs with four machine bolts; the base of the T protrudes through the curved wall and supports the treads. An engineer OK’d the bracket design, and the building department approved the stair.

The brackets are not all T-shaped. The bottom two are L-shaped, and the top ones are attached to the second-story floor joists, so they’re straight.

One stud per tread

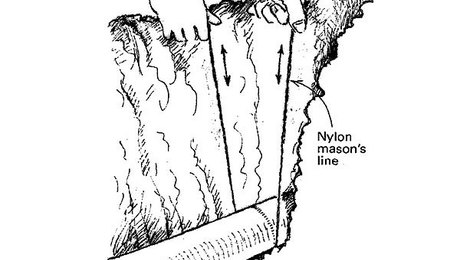

The cylindrical room was framed with 2x6s on 16-in. centers. In the area where the stairs project from the curved wall, I used doubled 2x6s to make 3-in, by 5-1/2-in. studs on 9-3/16-in. centers at the outside edge. Each of these studs bears a stair bracket.

The stud spacing is based on some fairly simple math. The stairs are laid out with a 6-15/16-in. rise and an 11-in. run. Because the treads are wedge shaped, the run is longer out at the railing than at the wall. The 11-in. run is at the center of the tread, where one is most likely to walk. All I had to do was figure out the run at the wall.

I knew the radius of the circle to the outer edge of the stud wall (96 in.). I also knew the radius of the circle at the center of the treads (115-1/4 in.). I knew the run of the stairs at the center of the treads (11 in.). I determined stud spacing with a ratio: 115.25 ÷ 11 = 96 ÷ x. The radius and the run at the center of the treads are directly proportional to the radius and the run at the wall. Putting in the numbers yielded 9-3/16-in. o. c. for the stud spacing.

The double studs were marked at the correct heights, using a builder’s level and a story pole, and then drilled out for the bolts that secure the steel brackets to the studs. The lapped portions of the brackets were let into the studs so that the brackets could be bolted tight to the studs.

For more photos and details, click the View PDF button below: