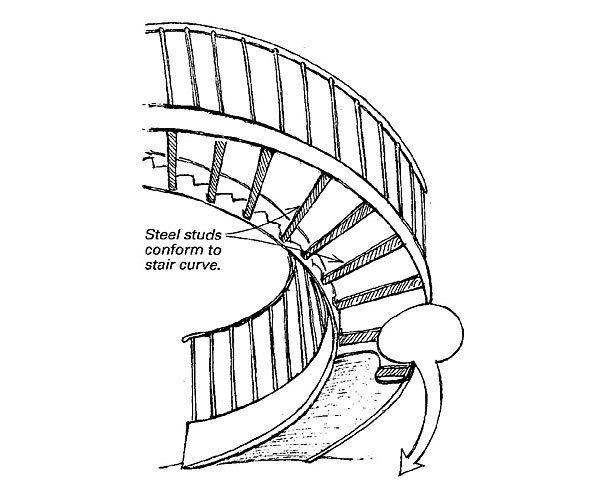

Our company builds three or four circular stairs a week, and often these stairs are finished with a drywall soffit on their underbellies. This is especially nice with a circular stair because it shows off the sweeping curve of the stair. Problem is, this plane is twisted, or more properly, it’s a helical surface. Builders often overlook this fact until the last minute, when the drywall crew shows up wondering how to affix the soffit to the stair. So how do you provide backing for a surface that’s constantly twisting?

The best solution I’ve seen yet is to use steel studs under every other riser. As shown in the drawing, a stud is clipped near its end and then folded up to form a flange. This flange is then screwed to the inside of the stringer. A corresponding flange at the other end of the stud is screwed to its stringer. The steel stud sort of rolls over between the stringers, making an almost perfectly twisted backing block. The floppiness of a metal stud becomes its value.

Thomas more Bujak, Palmyra, NJ