Making and Using Straightedges

These easily constructed tools help with building tasks from framing to finish.

Synopsis: Useful as cutting guides as well as for hanging doors and setting kitchen cabinets, straightedges are versatile tools for all kinds of framing and finish-carpentry tasks. This short article describes how to make and use them.

A carpenter once asked me, “What’s this funny piece of wood?”

“A straightedge,” I told him.

“What do you do with it?” he asked.

A better question, however, is what would I do without it?

When I’m framing, I use a straightedge for making layout lines in pencil instead of using a chalkline. Pencil lines are finer and can withstand the rain and the scuffing that can obliterate chalklines. A straightedge also is helpful when I’m straightening wall plates, checking stud alignment and plumbing walls. On occasion, I have used a straightedge as a cutting guide for my circular saw.

When I’m installing trim, my straightedge will warn me about bowed studs in finished walls, corners that flare out and dips and bumps in floors. This tool is a must when I lay out and set kitchen cabinets. A line drawn with a sharp pencil and a straightedge on a finished wall is much neater and more precise than a snapped chalkline. A straightedge can make aligning cabinet tops and fronts a snap, especially when the cabinets are not continuous, as in the case of a dishwasher void. I also use a straightedge to transfer plumb layout lines from floor to ceiling. If the straightedge is too short, I just slide my level up the edge that needs to be extended, and then I make my mark. Door hanging is another task in which the straightedge is essential, but I’ll discuss that in greater detail later in the article.

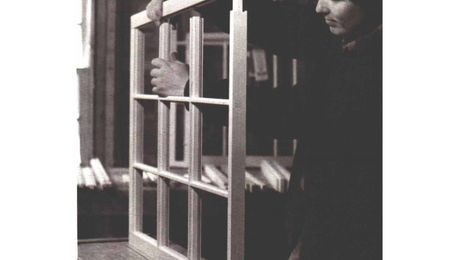

Making a straightedge in the shop

A common sight on the job is an 8-ft. strip of plywood used as a rip guide for a circular saw. Quite often, this same strip gets pressed into service as a straightedge. Although plywood may be adequate in a pinch, it’s generally too thin, too flexible and too likely to delaminate to make a good, durable straightedge.

Making a tough, reliable straightedge is not difficult. I begin with clear, straight-grained wood: White pine, poplar, redwood, Western red cedar and fir are all woods commonly found in house construction and are all good for making straightedges. Furniture-grade woods such as walnut or mahogany also work well. Knots, wavy grain and pithy wood all make it difficult to create and maintain a perfect edge on a piece of wood. So wood with any of these defects should be avoided for straightedges.

For more photos and details, click the View PDF button below:

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Large-Capacity Lightweight Miter Saw

11" Nail Puller

Reliable Crimp Connectors