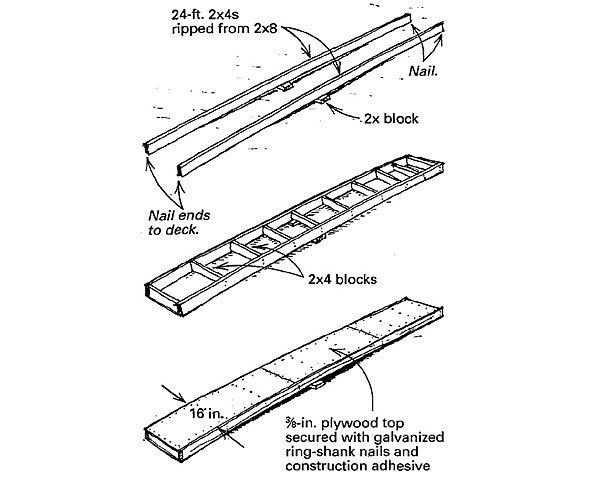

Whenever one of my jobs calls for scaffolding, I use staging planks held aloft by pump jacks. I make the planks out of material that is already on the job site, and I typically build several at a time so that I can gang-cut the parts and take advantage of my air nailers. As shown in the drawing, 1 start assembly with a couple of 2×4 stringers that I’ve ripped from a 24-ft. 2×8. In selecting the 2x8s, I look for straight grain and as few knots as possible. I put 2x blocks under the middle of each stringer, and then I toenail the ends of the stringers to the floor deck. This step puts some camber into the plank.

Next I add a row of 2×4 blocks, 13 in. long, between the stringers to provide rigidity and a nail base for the plywood deck. Then I rip a sheet of 3/8-in. plywood into three 16 in. by 8 ft. strips, and I affix the plywood to the frame with construction adhesive and 6d ring-shank nails. I use galvanized nails exclusively because the planks are sure to spend their entire lives outdoors. As a final touch, I use my garden sprayer to apply a coat of clear wood preservative to the planks.

Although these planks are heavier than comparable aluminum planks, at about $40 for materials they sure cost a lot less. When a plank eventually gets too tattered to use as staging, I cut it in half and use the pieces as worktables and miter-saw stations.

Skip Gibson, Barnstable, MA