I have seen many fence-post replacement techniques in the Tips column but never a solution to the challenge that I’m often confronted with: replacing a broken fence post when the break is at or below grade, and when the fence panels are still attached to the old post.

My customer’s project, a condo complex built on rock ledge, has had a continuing problem with poor drainage. The wet conditions severely weaken the white-cedar fence posts, and then the wind on the stockade-fence panels does the rest. I’m left with a soggy, disintegrating 2-ft. long cedar plug buried between two 6-ft. fence panels that are only inches apart, often at the edge of someone’s garden or next to a sidewalk.

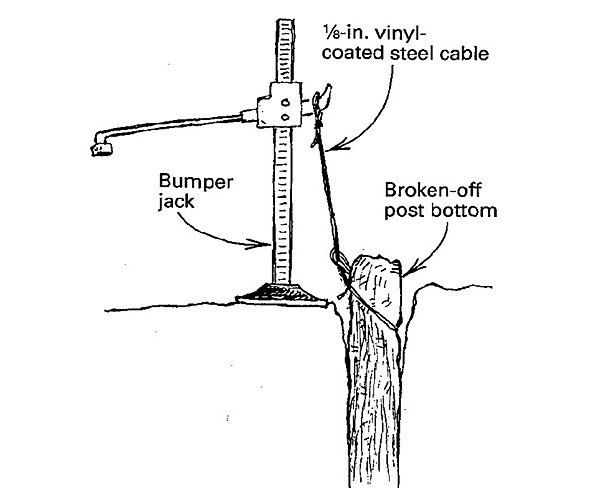

The first part of the fix requires a 2-ft. length of 1/8-in. vinyl-coated steel-wire cable and an auto-bumper jack. With a spade, I clear the soil from around the plug, exposing its top 6 in. or so. Then I form a noose on both ends of the cable, using small U-shaped shackles supplied by my hardware store for this purpose. One noose goes over the cedar plug; the other goes over the business end of the jack.

I position the jack as close to the hole as I can and start ratcheting. The vinyl provides a smooth-acting choke hold on the soggy cedar as the slack is taken up. The tremendous load provided by the suction on the plug will cause the jack to lean over the hole, but that’s okay. The vertical mast of the jack can be pulled back plumb without much effort. As the plug is slowly extracted, I loosen the cable and lower it on the plug for another bite. When the plug is out, a near-perfect hole remains for its pressure-treated replacement post (a much better choice, especially for locations that are wet).

Now it’s time to extract the rest of the post from the panels. Using the jack, I raise the panels as shown in the drawing. The fence panels are secured to the post by way of tenons on the panel rails. With the help of a handsaw, I bevel the bottom tenon on one of the panels, allowing the panel to come free as I raise the post. Yes, the panels do get temporarily wracked during this process, but they’ll move because they don’t have any diagonals in them.

Once I’ve got the panels raised enough to extract the post, I install the new one. The new post has mortises in it to correspond with the original post. I lower the post into the awaiting hole, threading the fence-panel rails into the mortises. Then I finish the job by running a few corrosion-resistant 3-in. screws through the post and into the rail ends.

When I was first asked to replace the rotten fence posts, I asked around for some advice. None of the fence guys I talked to had any solutions, and the bids to replace the fence came in at $55,000. Using this method, I’ve been able to maintain the fence for a considerable savings.

Bob Jepson Jr., Milton, MA