Building Hip and Valley Roofs With Trusses

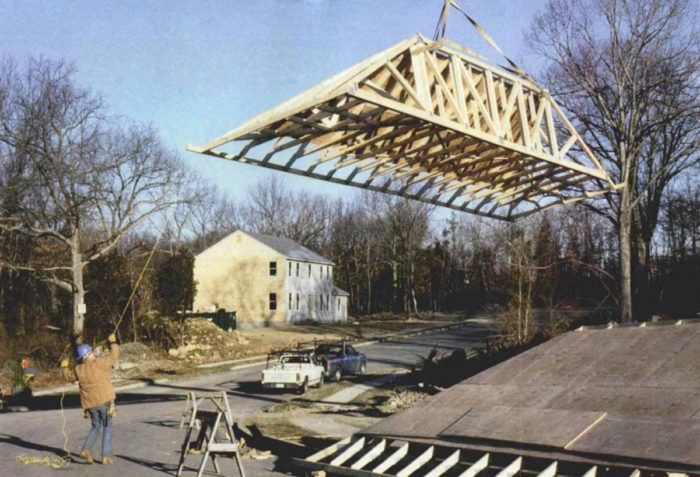

Keep the numbered trusses in order, and entire hip sections can be assembled on the ground and lifted as single units.

Synopsis: The author describes a complex hip roof that is formed with trusses on the ground, then lifted into place with a crane. He argues that building sections on the ground is both faster and safer than handling each truss on the roof.

A few years and many roofs ago, a builder approached us about framing a two-story colonial-style house. He said that he wanted to try a truss system for the hip roof. We had used trusses for a lot of gable roofs, but we had never seen a hip done that way. When the trusses for the job were delivered, we just stood back and scratched our heads. It looked as if bunches of unrelated pieces had been strapped together in no particular order. The engineering plan looked like a map of some unfamiliar suburb.

Too smug to admit that we needed help, we muddled our way through, lifting each weird looking truss up to the roof by hand and then moving each piece three or four times until we found the right spot to nail it. That roof is still in good shape after two hurricanes, and whenever we drive by the house, we chuckle at how much time and effort it took to put that roof together.

Our methods for assembling hip-and-valley truss systems have evolved a great deal since that first puzzled attempt. The biggest advance in our technique came when we described the process to our crane operator. He suggested assembling some of the trusses on the ground and lifting whole hip sections onto the house in one shot. It worked like a charm. Now we even sheathe the assemblies before they go up.

Building hip systems on the ground is quicker and safer

Before anything is assembled, we prep the hip-and-valley trusses much as we do standard trusses. We line them up in a stack on the ground and mark layout lines for the sheathing and strapping and for alignment on the walls. If necessary, we also restack the trusses that will be lifted individually by the crane to be sure they’re in the proper order. We lay out the wall plates according to the truss plan and write the number and designation for each truss at its layout point.

When framing hip roofs with trusses, we most often use a step-down hip truss system. Trusses in this system have the same span as common trusses, but they’re flat on top. The flat parts of the hip trusses become progressively wider and lower as the trusses step away from the last common truss to begin forming the hip. The lowest and widest hip truss, the hip-girder truss, supports a series of monotrusses, called jack trusses, that complete the roof. The hip-girder truss usually has a heavier bottom chord than the other hip trusses to accommodate the extra weight of the jack trusses and the metal hangers that hold the jacks. Generally, two girder trusses are nailed together and work in tandem for each hip system.

For more photos, drawings, and details, click the View PDF button below:

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Shingle Ripper

100-ft. Tape Measure

Peel & Stick Underlayment