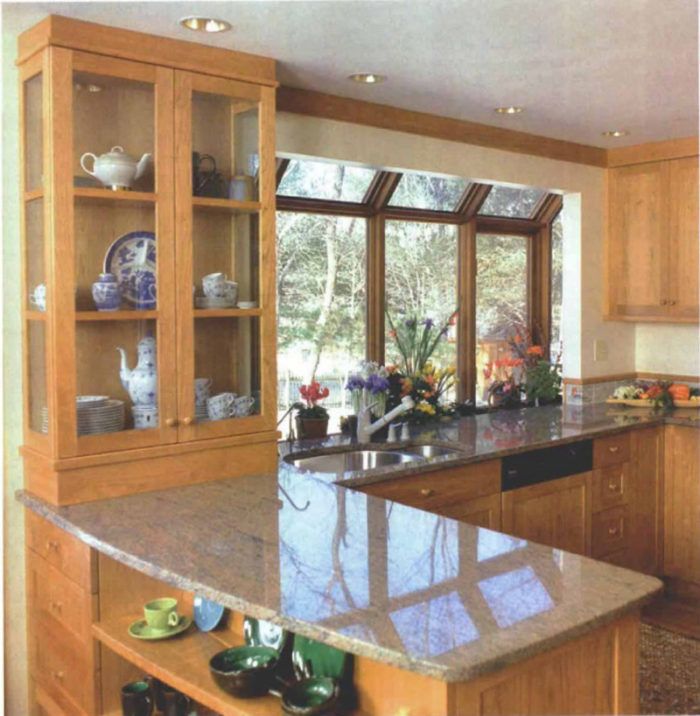

Granite Countertops

An experienced fabricator explains the process from the templating to the final setting of the slabs.

Synopsis: Granite has emerged as an expensive but extremely popular material for kitchen countertops. In this article, a stone fabricator describes the process of making templates, cutting, and installing slab granite.

For most of the past 20 years, my company has been taking the rockbound coast of Maine and bringing it into the homes we work on. Our specialty is granite, both rough and refined. We transform thin slabs of the material into beautiful, functional kitchen countertops.

Our shop is located in Orland, an area that once thrived on the granite industry. We’re surrounded by such historic quarrying towns as Frankfort, Blue Hill, Franklin, Jonesboro, Mount Desert and Deer Isle, source of one of the most structurally sound granites available. Granite from Deer Isle was used in the memorial to Robert Kennedy at Arlington National Cemetery.

I started working in the masonry division at Freshwater Stone & Brickwork in 1987 as a mason’s tender, later moved to the granite side of the business and now work as the company’s manager. I have found that there is something sweet in the smell of freshly split granite.

Not just a pretty face

Granite countertops are so breathtakingly beautiful that many people don’t realize what a practical choice they are. Granite is one of the hardest naturally occurring materials. It has a compressive strength of 19,000 psi (according to the non profit American Society for Testing and Materials). In other words, it takes 19,000 lb. of pressure in 1 sq. in. to break the material. A granite countertop will not scratch under everyday use; it can be used as a cutting board.

Dropping things on granite won’t damage the countertop, but I sometimes hear from customers who say I owe them a new coffee cup or dinner plate. Granite also withstands intense heat, so you can take pots right from the stove and set them on the countertop without fear of leaving burn marks.

When submerged in water, granite will absorb only 0.4% of its own weight in water, quite low compared with other building materials. What this means to the homeowner is that granite is naturally resistant to staining. Spilled liquids bead right up. And polished granite doesn’t promote bacteria growth. Warm, soapy water is all that’s needed for cleaning.

Color indicates composition

Granite is an igneous substance (formed by the solidification of molten rock) that contains mostly feldspar and quartz. The color in a slab of granite comes from minerals and organic matter, such as plant and animal life, present when the material was in the molten state. Shades of white and pink indicate a high proportion of feldspar. Gray stone contains a lot of quartz. High concentrations of biotite are present in black granite.

Granite blocks are cut from quarries with drills and wedges, huge cutting torches, wire saws and water-jet cutters. The quarried blocks are typically 5 ft. by 5 ft. by 10 ft. Blocks are trucked or shipped to processing plants where gang saws, a series of carbide-tipped blades spaced 1.5 in apart, often work 24 hours a day, seven days a week, slicing the blocks into slabs. The slabs are then polished on one side and put into a huge inventory.

For more photos and information about granite and its cost, click the View PDF button below.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Original Speed Square

Anchor Bolt Marker

Plate Level