Q:

I’d like to build some storage area in my garage above the car-parking area. The garage is 20 ft. wide. The 2×6 studs, 2×8 rafters and 2×10 joists are all 2 ft. o. c. On one side of the garage, the joists rest on the wall plate. On the other side, however, the rafters are longer, and the joists are nailed to the rafters at around 2-1/2 ft. in from the wall, putting the total joist span at 17-1/2 ft. How can I modify the framing so that I can use the area above the joists for storage?

Peter R. Dodd, Sunapee, NH

A:

Christopher DeBlois, a structural engineer with Palmer Engineering of Chamblee, Georgia, replies: Your situation raises several structural questions. First, the 24-in. spacing of the framing combined with a snow load of 45 lb. per sq. ft. (psf ) for your roof would normally be problematic, but the 2×10 rafters and 2×6 studs should be adequate. Also, the plywood sheathing on the garage walls should provide excellent bracing for the studs, giving them plenty of capacity to handle the extra weight from the proposed storage loads.

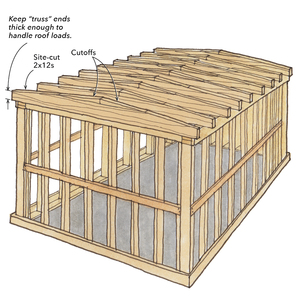

The 2×8 ceiling joists by themselves are definitely not ready for plywood and Christmas boxes, but doubling them will provide enough capacity to handle a live load of 20 psf, which is consistent with light storage. (I’d think twice about using the space to stash file cabinets filled with years of tax records or the engine from that ’57 Chevy you’ll eventually finish rebuilding.)

The most complicated part of this problem is how the joists are connected to the rafters and what the weight of the joists will do to the rafters. Face-nailing the joists to the rafters is fine when they are acting just as heavy collar ties. However, transferring the load from your new storage space by facenailing is really a different story.

The numbers say that face-nailing can transfer the necessary 250 lb. per joist. Just make sure that the new joists are nailed in on the opposite side of each rafter from the existing joists and that each joist is face-nailed to the rafter with three 16d nails. For added insurance, I recommend scabbing 2x10s along both sides of each rafter from the top of the wall plate to the underside of each floor joist. The 2x10s should fit tight at the top and bottom and should be face-nailed to the rafters as well. Without this blocking to help transfer the weight of the joists, I would not be comfortable with the connection. Relying just on the face nails would be about the same as balloon-framing without a continuous ribbon let in to the studs to support the joists.

An equally important but more subtle problem is the capacity of the rafters to carry the load from the joists and storage in addition to the weight of the roof itself, plus the snow load. Even though the load from the joists comes into the rafters just 30 in. from the bearing wall, the extra weight from the floor increases the design stress in the rafters by a whopping 40%. Luckily, your rafters are somewhat oversize for your roof. Lumberyards don’t carry 2x9s, so your 2×10 rafters leave some reserve capacity and, in your case, just enough reserve to accommodate light storage.

The more important message here lies in the geometry of the framing. Span charts for lumber are based on conditions of uniform load only. Introducing a point load (for example, by framing a floor into the rafters several feet up from the wall plate) means the rafters are being asked to do double duty, and you can throw those span charts out the window. How can you tell if the rafters are being asked to work too hard? Your best bet probably is to have a structural engineer review the geometry and size the rafters accordingly.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Stabila Classic Level Set

Magoog Tall Stair Gauges

Bluetooth Earmuffs