Details for a Lasting Deck

Government scientists study outdoor structures and report on which details, fasteners and finishes hold up best.

Synopsis: This article looks at construction details that go into building a durable exterior deck, including methods for connecting beams and posts, what types of fasteners are best, and how to apply finish. The authors are structural engineers at the USDA Forest Products Laboratory in Madison, Wisconsin.

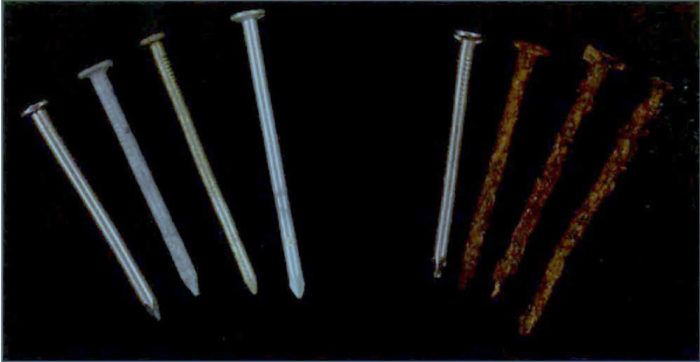

Some decks need major overhauls after less than 10 years. Others stay strong and good looking for decades. What’s the secret? Well, besides the obvious first choice of suitable lumber (we recommend either a naturally durable species or preservative-treated lumber), a lasting deck is put together with strong, durable fasteners, and it gets regular applications of a penetrating finish to repel moisture and to minimize the effects of the weather.

Although the structure of a deck is a lot like the skeleton of a conventionally framed wood house, a deck doesn’t have the stability of sheathing, and there’s no roofing and siding to protect it from the elements. That’s why decks require extra care and attention to detail. As wood researchers at the U. S. Forest Service Forest Products Laboratory, my colleagues and I have studied lumber, construction techniques, fasteners and finishes. From this research, we offer some recommendations for building decks that last.

Start with good connections

In wood construction, connections often limit strength; so many common failures of deck construction lead back to connection performance. Proper connections of deck joists to beams, beams to posts and decks to houses are critical.

Because fasteners and hardware in wood decks can corrode, it’s prudent to minimize dependency on them. Wherever possible, joists and beams should bear directly on posts. This type of connection requires more vertical space, but it’s more reliable than transferring load through fasteners.

There are a number of ways to connect beams to posts. Two-by lumber can be used as a beam if either set directly on top of the post or let into a notched post. This notched connection only works when the posts are 6×6 or better because notching a 4×4 post with 2x side members leaves only 1/2 in. of post for you to bolt through.

A better option when supporting a built-up beam with a 4×4 post is nailing a 1/2-in. treated wood spacer between the two 2xs and setting the beam directly on top of the post. You also can tie the connection together with a hot dipped galvanized beam-to-post connector. Just remember, though, that whenever you cut notches or install lag screws or bolts in deck lumber—even if it’s preservative-treated lumber— you should treat the openings in the lumber with a wood preservative.

The connection at the house must be detailed carefully

Attaching a deck to a house is risky business. Screwing or bolting into a house opens the siding’s protective envelope to moisture, which can lead to decay and insect attack. Wherever practical, it’s best to build a freestanding deck.

If a freestanding deck isn’t feasible, take extra care attaching the deck to the house. And although it probably goes without saying, nails aren’t adequate to make this connection.

To prevent water from entering the house, it’s important to caulk pilot holes in the band joist of the house before installing screws or bolts. It’s also prudent to add spacers, such as a few washers, between the two structures to allow the gap between the deck and the house to dry. You also should extend metal flashing under the siding above the deck and over the siding below the deck.

For more recommendations for building decks that last, click the View PDF button below.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

MicroFoam Nitrile Coated Work Gloves

Metal Connector Nailer

FastenMaster Screw Bolt Fastening System