Most of the crown-molding articles that I’ve read in Fine Homebuilding focus on the methods used to get the corners to fit correctly. I find that it is sometimes harder to execute a good scarf joint in the middle of a run of crown molding. For me, the solution to this problem is the biscuit joint.

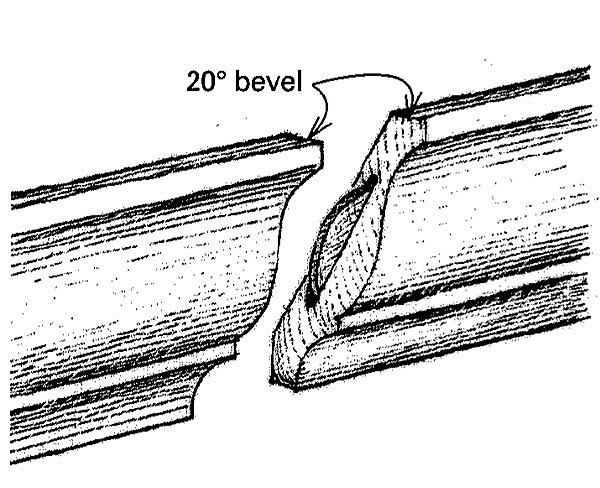

As shown in the drawing, I bevel the mating pieces at 20°. I make biscuit slots in the pieces by laying them flat on a smooth surface and then placing the biscuit joiner on the same surface. Thinner moldings sometimes have to be elevated slightly by placing them on a piece of 1/8-in. plywood.

I set my biscuit joiner on maximum depth to make the biscuit slots. Using the maximumdepth setting allows me to make the cuts after the bevel cuts have been made. Even with this extra depth, I can get only a #10 biscuit into the cut, but that’s all I need.

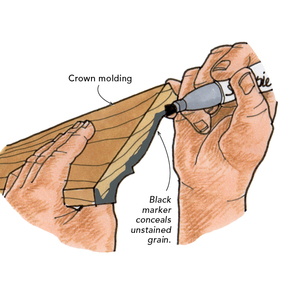

During installation, I secure the first piece of crown and then cut the second piece to the correct length. Once I’ve cut the second slot, I assemble the two with biscuit and glue. The biscuit holds the alignment in the right place, allowing me to work quickly even when working solo. Once the glue has cured, I fine-tune the joint with scrapers and sandpaper.

Jeffrey H. Lunin, Washington, DC