Raising Panels with a Router

Donald Brown offers an alternative method for raising panels.

In his article, “Making Cabinet Doors with Router Bits,” Jud Peake fairly and accurately presents the pros and cons of raising panels with both “horizontal” and vertical” router bits. Peake opts for the horizontal bit primarily for the ease of holding the panel flat to the table.

I, on the other hand, chose the vertical bit because I was intimidated by the great whirling mass of steel that is the horizontal bit. Like Peake, I was dissatisfied with the wavy cut that often results when using the vertical bit. It’s just difficult to hold the panel absolutely flat to a vertical fence.

Another Approach

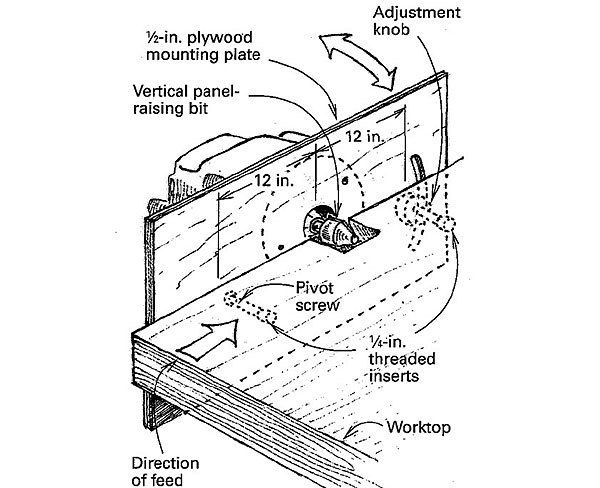

To regain the advantage of a horizontal work surface, I mounted my router at 90° to the conventional setup. As shown in the drawing, I affixed the router to a piece of hardwood plywood. The base of the router rests in a shallow recess routed into the plywood.

The plywood mounting plate is attached to a 2-in. thick top by way of two 1/4-in.-dia. machine screws driven into threaded inserts embedded in the top. One screw acts as a pivot point. The other projects through a slot in the mounting plate. A washer and a large knob on this screw allow the mounting plate to be clamped at the desired height relative to the work surface.

The router bit should be below the work as the panel is passed over it, and the cut should start out shallow and be increased gradually until the final depth is reached. Notice that the locking point is twice as far from the pivot point as the center of the router bit. At this relationship, raising the plate 1/4 in. at the locking point lifts the bit 1/8 in. I made some marks on the back of the mounting plate to act as a depth scale, which makes it quick and easy to gauge the depth of the cut.

— Donald C. Brown; Ruckersville, VA

From Fine Homebuilding #103

RELATED STORIES

- Making Raised-Panel Doors on a Tablesaw

- A Simple Approach to Raised-Panel Wainscot

- Making Cabinet Doors with Router Bits

Got a Tip?

Do you have any great tips like this one on how to raise panels with a router? Share your methods, tricks, and jigs with other readers. Tag them @FineHomebuilding on social, email them to us at tips@finehomebuilding.com, or upload them to FineHomebuilding.com/reader-tips. We’ll pay for any we publish.

View Comments

Good man, very cool. I'm not a member and did not see the video. MLCS has offered these router tables for years.

https://www.mlcswoodworking.com/shopsite_sc/store/html/smarthtml/pages/horizontal_router_table.html#horiztab_anchor

A raised panel supported on a large horizontal work surface is always best. The bit illustrated could, of course, be used vertically with a vertical panel, but is best used horizontally as the author recommends.

Most raised panel bits with which I'm familiar, being shallow with a large diameter, are designed for vertical rotation and to be used with a horizontal work piece.

Using a piece of of laminate counter top makes a very good surface to slide the panel on, and adding an elevator screw makes for more accurate adjustments.