Restoring Wood With Epoxy

Instead of tearing out and replacing rotten wood, you can fix damage and make wood look as good and last as long as new.

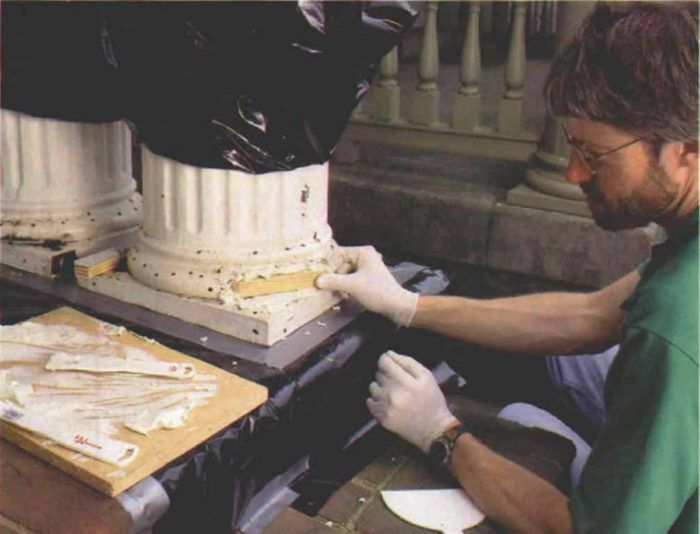

Synopsis: A restoration specialist explains the benefits of epoxy wood repair, showing how building components seemingly ready for the scrap pile can be salvaged. He tackles three easy-to-understand projects and adds an annotated sources-of-supply sidebar.

Give me liberty or give me death!” On March 20, 1775, Patrick Henry spoke those immortal words in a small church here in Richmond, Virginia, galvanizing the second revolutionary convention to fight for independence from England. As a carpenter living and working in Richmond’s historic Church Hill district, named for the church where Patrick Henry delivered those famous words, I am constantly bombarded by history.

As a lover of history, I am both fascinated and humbled to know that many of the structures I work on have borne witness to profound events. So when I’m asked to rip out and replace a piece of weather-damaged woodwork where a soldier may have leaned a war-weary shoulder, I try to find an alternative. High-strength epoxies offer that alternative whether the wood you’re fixing is 20 years old or 200 years old. With apologies to Mr. Henry, I have to say, “Give me epoxy.”

Epoxy isn’t for all repairs

Epoxy for wood repair has been around for decades and is routinely specified on major historical-restoration projects nationwide. One manufacturer, Abatron, has been making epoxy wood-repair systems since 1959.

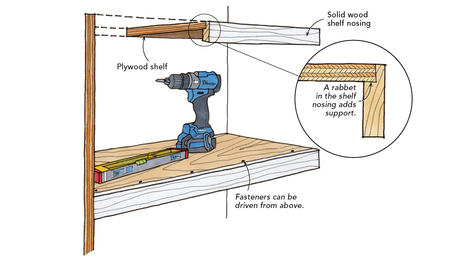

In the simplest terms, an epoxy repair goes something like this. After loose, crumbly wood is removed and sound wood is dried, a liquid consolidant is applied to impregnate and strengthen rot-damaged wood. Then a puttylike compound fills the gaps, replacing the missing wood.

The most common complaint I hear from people who’ve attempted an epoxy repair is that “the damn stuff all fell out.” But after using epoxy wood-repair systems for many years, I’ve found that if procedures are followed carefully, epoxy is almost as wonderful as the advertisements claim. But when instructions aren’t carried out carefully and dutifully, indeed, the damn stuff may all fall out.

Epoxy does have its drawbacks. First, it’s expensive, at least 50¢ per fluid ounce, and that’s for large quantities. Also, in many cases the repair procedure is more complex and time-consuming than a simple cut-and-replace job. In my opinion, some rotten-wood situations, such as framing lumber, square porch posts and stock railing parts, are usually easier to replace than to repair with epoxy, unless removal of the damaged wood is difficult, the damage is minimal or George Washington’s initials are carved into the damaged wood.

Epoxies can also be used for major structural repairs such as rebuilding the tenons on large beams in historic timber frames. In these repairs a special epoxy that cures harder than conventional epoxy is combined with gravel, fiberglass reinforcement rods or metal plates to effect the repair. Structural repairs with epoxy require special skills and should be done by epoxy experts with the approval of a structural engineer.

For more photos and details, click the View PDF button below: