Framing Floors With I-Joists

Whether you're building a new house or remodeling an old one, engineered lumber can give you squeak-free floors with fewer callbacks.

Synopsis: I-joists offer some advantages over floor joists made from dimensional lumber, especially in long spans, but working with them requires learning a few new tricks. This primer on framing floors is good background reading for anyone who’s getting ready to order this engineered material but isn’t exactly sure how to work with it.

Most people wouldn’t think twice about spending a couple hundred dollars on a computer upgrade that might be obsolete shortly. But the same people would labor for weeks deciding whether to spend a like amount upgrading the quality of a new home by using wood I-joists instead of standard lumber for floors.

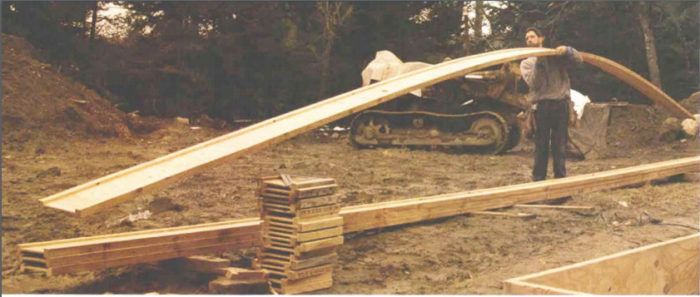

I-joists are a bit scary the first time you handle them. Short 3-ft. or 4-ft. pieces seem sturdy enough, but 30-footers flop around like al dente linguini. I-joists take a little more care to install than dimensional lumber, but when installed properly, they produce a stronger, flatter and stabler floor deck than one framed with the best kiln-dried dimensional lumber.

I-joists can be part of an engineered floor system

I-joists are one component of the engineered-wood floor systems manufactured by numerous companies. There are small differences between floor systems from one manufacturer to the next, but we haven’t found those differences critical enough to affect either performance or installation.

Besides the I-joists, two other components combine to form engineered floor systems. The first is the main beam or girder that carries the joists. In a conventional deck, the main beam usually consists of layers of dimensional lumber such as 2x10s sandwiched together. In an engineered floor system, LVLs (laminated veneer lumber) or PSLs (parallel strand lumber) are used instead. LVLs and PSLs span greater distances and are more stable than beams made with conventional lumber.

I-joists can be installed over dimensional lumber carrying beams, although manufacturers of engineered floor systems caution against it. If, however, the center beam is installed infloor or in the same plane as the I-joists, with the I-joists hung from the sides of the beam, a PSL or LVL beam is a must.

The other element of an engineered floor system is tongue-and-groove plywood or OSB structural panel—with the APA Sturd-I-Floor rating— that goes over the joists. Here again, conventional structural panels can be used over I-joists, but it goes against manufacturers’ recommendations. Also, putting Sturd-I-Floor sheathing down using construction adhesive and the proper nailing schedule actually increases the allowable span of the joists.

As the name implies, I-joists are shaped like the letter “I.” The vertical sections are called webs, and the horizontals are the flanges. I-joists come in a variety of sizes, and those with larger webs and flanges can carry larger loads and span greater distances. Manufacturers assign a series number to each size indicating the strength and spanning capabilities of the joist. But be careful when comparing companies’ I-joists. Series numbers are not standard from one manufacturer to another.

For more photos and information on framing floors with I-Joists, click the View PDF button below.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Guardian Fall Protection Pee Vee

Protective Eyewear

Tajima Chalk Rite Chalk Line