Q:

I have a wood shop in the basement of my house. My wife has yet to develop an appreciation for the sweet whine of the table saw or the winsome wail of my thickness planer. Earplugs are not an option for my wife, so what is the best way for me to reduce noise transmission through the ceiling?

Mark G. Loch, Marietta, OH

A:

Former associate editor Roe A. Osborn replies: I was the fourth of five noisy kids in our family, and when my dad converted part of our basement into a recreation room, he was as much interested in containing our noise as he was interested in giving my siblings and me a place to play. An amateur carpenter, my father chose to run 1×3 strapping under the floor joists 1 ft. o. c., and then he stapled 1-ft. square acoustical tiles to the strapping, creating a quick, simple and effective solution.

Acoustical tiles could work to keep out tool noises as well, but there are a couple of other things I’d try. First, if the basement ceiling isn’t insulated, adding unfaced insulation can do a lot to dampen noise, and you’ll have warmer floors as a result. You may find that this measure adequately reduces the shop noise and appeases your spouse. The downside to leaving insulation exposed over your shop is that it constantly showers fine fiberglass dust and that the insulation tends to catch airborne sawdust. I remedy this situation by stapling landscape fabric, which does not trap moisture, to the bottoms of the floor joists below the insulation.

If insulation alone doesn’t cut the noise level sufficiently, dear old dad’s acousticaltile treatment might be in order. A suspended ceiling with acoustical panels would also work, but this option can rob headroom, which is usually at a premium in a shop.

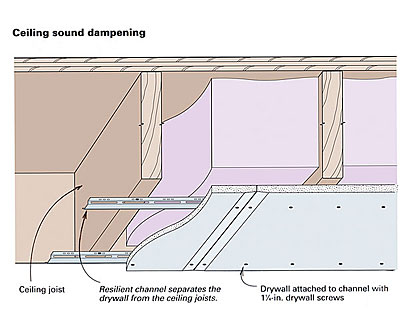

Perhaps the most effective way of reducing noise transmission is by running resilient metal channel under the joists and attaching drywall to the channel. The channel effectively suspends the drywall between the shop and the floor so that sound hitting the drywall won’t be transmitted to the floor above.

Resilient channel, available at drywall-supply stores, has a U-shaped profile with an attaching flange along one edge. The channel should be run on 12-in. or 16-in. centers and screwed into every joist. The drywall should then be attached to the channel with screws no longer than 1-1/4 in. so that they don’t bite into the joist. Because the ceiling is going over a woodworking shop, it wouldn’t be a bad idea to spend a few extra bucks for fireresistant drywall.