A Walk Through Wood Floors

Strip oak is not the only option, but without some guidelines, choosing among strip, plank, prefinished, solid and engineered floors can be tough.

Synopsis: Here’s a look at several types of wood flooring on the market, including descriptions of strip and plank flooring, pre-finished, engineered flooring, recycled flooring, and bamboo flooring. It makes for good reading before buying.

During the building boom of the late 1940s and the 1950s, carpeting and synthetic sheet material replaced wood flooring as America’s flooring of choice. These floor coverings were much quicker and easier to install than labor-intensive wood-strip floors, and Americans got used to the feeling of fuzz under their feet.

But carpet requires constant maintenance (vacuuming), and its very nature makes it difficult to clean. Warm, fuzzy carpet can support whole cities of microscopic dust mites that cause allergic reactions in humans. And even the best grades of carpet show signs of fatigue after only a few years. The desire for flooring that is more permanent, easier to keep clean and more conducive to a healthful indoor environment has folks returning to wood floors.

But a spin through the wood-flooring section of your local home center or flooring supplier can be extremely confusing. You’ll have to navigate through choices in wood species, color, composition and finish, as well as installation methods to come up with a wood-floor decision that will suit your circumstances, your taste and your budget.

Start with the finish

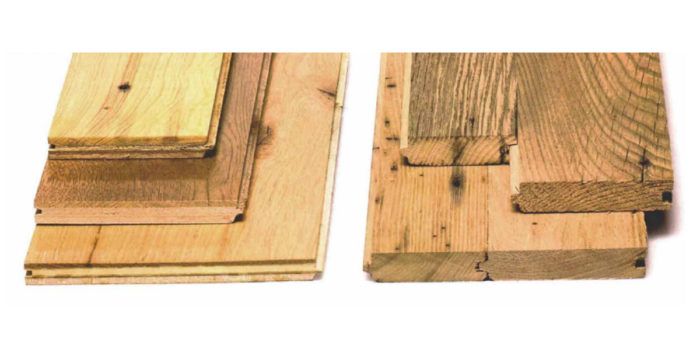

Wood flooring comes either unfinished, which requires sanding and finishing after it is installed, or prefinished in the factory. Unfinished flooring is still the most popular type of wood flooring. At first glance, unfinished-wood flooring seems like the obvious choice from an off-the-shelf cost standpoint. At home centers here in western Connecticut, unfinished oak strip flooring goes for about $1.80 to $2.50 per sq. ft. But unless you plan to install, sand and finish the floors yourself, figure on that price at least doubling when the installer and finisher weigh in.

With unfinished floors, the quality of the final finish depends entirely on the installer, the type and grade of finish used, the number of coats applied and the care taken with the application. That adds up to a lot of variables. Polyurethane is the most common finish, and polys are either water based or oil based. Oil-based polys take longer to dry and produce noxious fumes, but they penetrate better into the wood surface. Water-based polys dry quickly and produce fewer fumes and a harder finish, but the water tends to raise the grain in the wood, so the floor requires more sanding between coats.

Some installers will also do special oil or wax finishes. These finishes are not as harsh looking as the more shiny polyurethanes. Also, high-traffic areas can be refinished and blended in seamlessly with the rest of a floor that has a wax finish. With a polyurethane finish, refinishing one area usually means refinishing the entire floor.

For more photos and details, click the View PDF button below:

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

A House Needs to Breathe...Or Does It?: An Introduction to Building Science

Homebody: A Guide to Creating Spaces You Never Want to Leave

All New Bathroom Ideas that Work