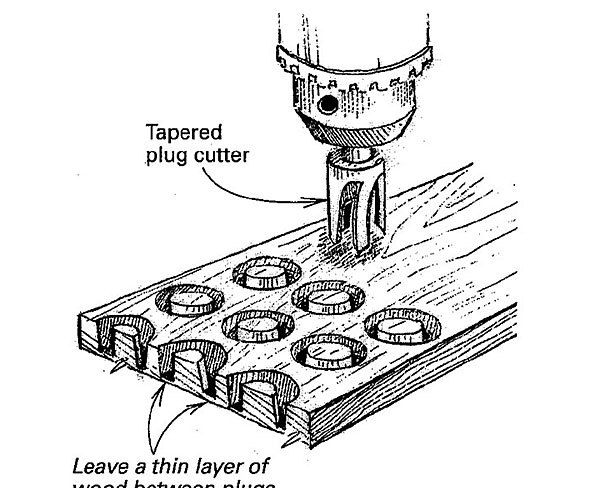

Making your own plugs for flooring or furniture is a real convenience for a woodworker. But if you need more than just a few, it can get pretty tedious to remove the plugs individually from the cutter. As shown in the drawing, I cut my plugs by boring almost all the way through a piece of stock. The thin layer of wood on the backside holds the plugs together while I cut a bunch of them.

I’m lucky enough to have a thickness sander, which I use to remove the thin layer of wood that unites the plugs that I’ve made. If you don’t have a thickness sander, a belt sander can get the job done. And if you don’t need a perfectly smooth face on the plug, you can use a screwdriver to pop the plugs out individually. By the way, marking the smaller-diameter side of the plugs before detaching them makes it easy to identify which end of the plug goes into the hole first.

James A. Hassberger, Livermore, CA