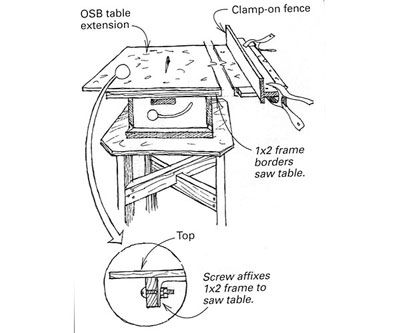

Every now and then, I have to use my portable tablesaw to cut wide, lightweight sheet goods, such as rigid-foam insulation. Trouble is, the saw’s top isn’t wide enough to accommodate sheet goods. As shown in the drawing, I made a temporary saw table that extends the work surface substantially on the right side of the blade.

The top is made of 1/2-in. oriented strand board (OSB). It’s screwed and glued to a 1×2 frame that fits tightly around the saw’s table. Most of the weight of the auxiliary table is on the right side of the saw. So to keep the OSB table from lifting, I bored a hole through the frame on the left side of the blade. A machine screw fits through this hole into a corresponding hole in the saw table, as shown in the inset drawing. A clamp-on fence made of 1x pine completes the rig. Now it’s a cinch to cut 23-in. wide sheets of foam to vent a ceiling.

Robert Conrad, Pellston, MI