Installing Floor Trusses

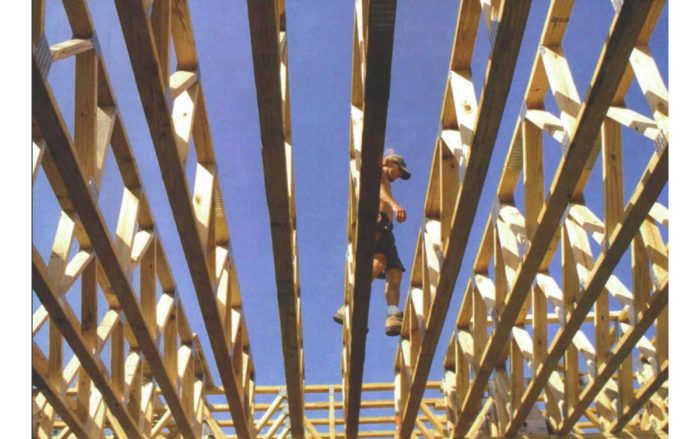

Parallel-chord floor trusses are more stable and span greater distances than stick framing, and speedier setup offsets their higher cost.

Synopsis: Parallel-chord floor trusses span greater distances than dimensional lumber, but they call for slightly different framing techniques. This article shows how they should be installed and includes a sidebar on how openings in the floor should be handled. Find more information about working with engineered floor joists in the article: Floor-Framing Design

As a framing contractor, I think speed and efficiency are my most important considerations. I’m not wasteful, but I don’t care as much about the cost of the material as the speed with which I can put it together. Although parallel-chord floor trusses are more expensive than conventional floor joists, my five-man crew can set the floor trusses for a 2800-sq.-ft. house and nail down the plywood subfloor all in one day, for labor savings of 25% over 2x joist installation. I believe those labor savings more than offset the extra expense. What’s more, I believe we end up with a stronger floor.

There are several reasons that floor trusses can be installed faster. Trusses are engineered to exact lengths, so no blocking and cutting are required. As a bonus, their webbing—the diagonal and vertical 2x material inside the truss—provides more than enough room for wiring, plumbing, and mechanicals, which means there should be no ill-planned cutting, boring, or notching to repair later.

Trusses are not without their weaknesses—chiefly that they can’t be cut or modified in any way—but their strength means fewer bearing walls, which also makes the job go faster. Trusses are relatively light and easy to handle, and they require no furring out for drywall. And you should have no callbacks because of squeaky or bouncy floors.

Also, trusses are more stable over long spans than conventional stick framing, and their open-web design makes adding wiring, plumbing, and mechanicals simpler than wood I-joists. Also, the top chord of a floor truss provides plenty of nailing surface for the decking.

Trusses are engineered for each job

To order trusses, the general contractor gives the manufacturer’s representative a complete set of plans. The representative then hands the plans off to an engineer, who designs the trusses based on the spans and the loads for my application. For instance, if a homeowner wanted to put a whirlpool in the master bath, the engineer might specify two trusses directly beneath the tub or drop the spacing down from 24 in. o. c. to 16 in. o.c. or even 12 in. o.c.

All floor-truss installations begin with this plan. On the plan, each truss is numbered or lettered to correspond to its location. Trusses arrive at the job site marked with numbers or letters that correspond to their place in the plan. When they’re delivered, however, the trusses often are out of order. If we have a crane to lift them, we’re in pretty good shape. But if we’re lifting them by hand, it’s a real pain when the trusses we need to set first are buried beneath the ones we’ll set last.

For more photos and details, click the View PDF button below: