Making Lumber With a Bandsaw Mill

One alternative to the high cost and poor quality of lumber these days is finding the trees and cutting them into boards yourself.

Synopsis: Using a portable bandsaw mill to make lumber from trees cut locally is one way of beating the high cost and declining quality of lumberyard material. This article is a quick look at the process, with a helpful list of manufacturers who can steer you to a sawyer in your area.

There’s a whole section of my property covered with neat stacks of lumber that I’ve cut on my bandsaw mill either to sell or to use in my building business. To justify the time I spend milling wood, I always tell my wife that these stacks of wood are like money in the bank. Now whenever we’re driving around and we see piles of stickered lumber in someone’s side yard or at the edge of a field, she always says, “Look, dear, there’s another branch office.”

For many years, I took any logs I needed to have cut into lumber to a circular-saw mill just down the road. But the sawyer who ran the mill retired, and his son hasn’t shown any interest in keeping the mill running. Faced with no local sawmill and frustrated by the quality of commercially sawn lumber, I decided to purchase a portable bandsaw mill for about $10,000. I found a slightly used Wood-Mizer bandsaw mill in my price range, and since then, I’ve been making most of the lumber I use in my business — from large timbers and framing to finish stock for cabinets and trim.

Bandsaw milling is not just for sawyers

Working with that old sawyer really put the process of making lumber under my skin. I thoroughly enjoy the whole lumber-making operation: obtaining the saw logs, moving them to the sawmill, performing or helping with the sawing and properly stacking the sawn lumber.

Although I’ve found that being a part-time sawyer is fun and rewarding, you don’t necessarily have to own a bandsaw mill to enjoy the benefits of one. With just a phone call, most bandsaw-mill companies can refer you to a sawyer in your area who can take care of most of your lumber needs.

I sell only a small amount of the wood I cut. In those cases customers call with a request for lumber, and usually I’m able to go to my stacks and find something for them. But unlike retail lumber stores or large local circular-saw mills, I don’t sell enough lumber to justify stocking all lengths and dimensions. What I do offer is full-dimension lumber usually better than what’s at lumber stores at below lumber-store prices.

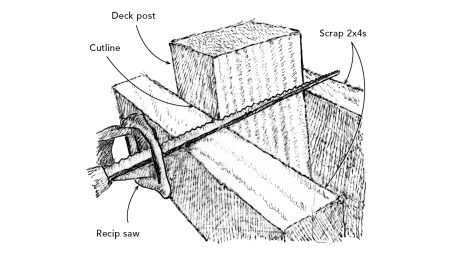

Other customers who come to me are in need of custom-cut lumber. Cutting a timber for a mantelpiece that needs to be, say, 9 3/8 in. by 11 7/8 in. is not a problem for a bandsaw mill. With a sharp blade and the mill properly tuned, tolerances of 1/8 in. or less are well within a bandsaw mill’s capabilities. Custom milling produces less waste, and the bandsaw blade also leaves a smoother surface than a circular lumber-mill blade.

For more photos, illustrations, and details, click the View PDF button below:

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Original Speed Square

Anchor Bolt Marker

Plate Level