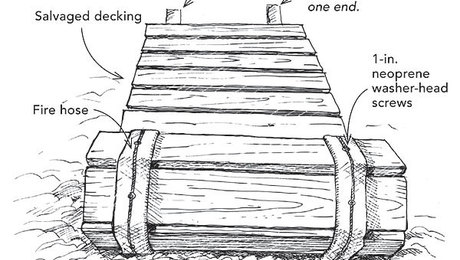

I own a Victorian house that needed some exterior trim repaired. One detail that was in an especially sad state was the 12-in. wide fascia that runs under the roof eave. The original had a couple of beaded details in it, along with a cove at the top. Rather than try to duplicate this fascia with an expensive, milled reproduction, I decided to make a built-up version with readily available materials. The key elements in the reproduction were PVC pipes.

As shown in the drawing, I sandwiched 1-in. dia. and 1/2-in. dia. pipes between wood members. The individual pieces are attached from the back to a 12-in. wide piece of lauan mahogany. I used galvanized screws to affix the pipes to the mahogany base, and then I sanded the pipes to give them a rough surface for better paint adhesion. Then I prepainted the fascias and installed them with stainless-steel screws. The result is a band of trim that looks right at home on the house at a fraction of the cost of a reproduction molding.

—Earl Sepella, West Chester, PA

Edited and illustrated by Charles Miller

From Fine Homebuilding #117

View Comments

Tremendous example of thinking "outside the box" and a great example of "problem solving". As an educator, it is very difficult to teach these skills.

I want to add that when I have to paint plastic, rather than scuffing or using a special primer for plastic, I simply hit it with a rattle can of paint formulated for plastic (Krylon, for example). Then I can paint it any colour I want.--most paints contain primers so they adhere well to other paints.

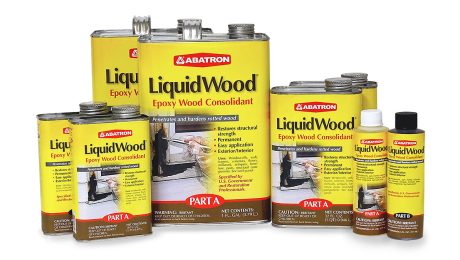

My concern would be the expansion/contraction of plastic vs wood. Maybe 1/2 round or dowel would be a better choice but might cost more.

I've seen pvc cut to replicate large cove moulding. I had to replicate trim to match ornate mouldings in a classical revival house in Portland, Maine, using small 1/4 round, closet poles ripped in half, built up 1/4" plywood, and milling coves in 3/4" stock. After lot's of caulking, quarts of wood filler, sanding, and a few coats of paint, running about $4/lf, it was still less expensive than custom milled moldings. Good thing the labor was free.