Replacing a Chimney Cap

Homeowners rarely see their chimney caps, and few people have ever called me to repair them. But when I'm asked to inspect a roof or an attic, I generally find myself looking down at the top of the chimney.

Synopsis: A deteriorating chimney cap can lead to all sorts of trouble as water works its way into masonry and freeze-and-thaw cycles do the rest. This article explains how to make a new mortar cap with a simple wooden form and strategically placed steel reinforcement.

Chimneys are built like heavy little houses.They have walls and a roof so that they stay dry inside. The roof, or cap, is usually a low-slope mortar bed suspended between the flues and the exterior walls. Often, these caps are built poorly and deteriorate rapidly. When the caps break and leak, water flows into the masonry walls, staining the exterior with salts from the mortar. Combustion residue that washes off the flue tiles can flow inside the house to produce stains and odors. In cold climates, soaked bricks freeze, split and spall. The whole chimney can really take a beating.

Homeowners rarely see their chimney caps, and few people have ever called me to repair them. But when I’m asked to inspect a roof or an attic, I generally find myself looking down at the top of the chimney. Obviously, leaks here should be stopped before new roofing or insulation is installed.

Protect the roof during the job

Repairing the cap can be messy work. Unless it is about to be replaced, the roof should be protected from foot traffic, tools and wet cement. Working on roof-mounted tarps or drop cloths is not recommended. On lower slopes, I sometimes stand on cleated sheets of plywood or oriented-strand board (OSB) that is supported by roofjacks. When the roof is too steep to stand on, you can work tarps around roof brackets and planks to provide coverage without compromising safety.

By the time I get an order to replace a chimney cap, it is usually so thoroughly destroyed that demolition is a minor concern. A few taps from a 20-oz. hammer are all it takes to clean it off. And because little material was used to make these old caps, the remains fit nicely in an old drywall bucket. After the loose, broken and missing bricks are fixed and dusted off, I can begin the formwork.

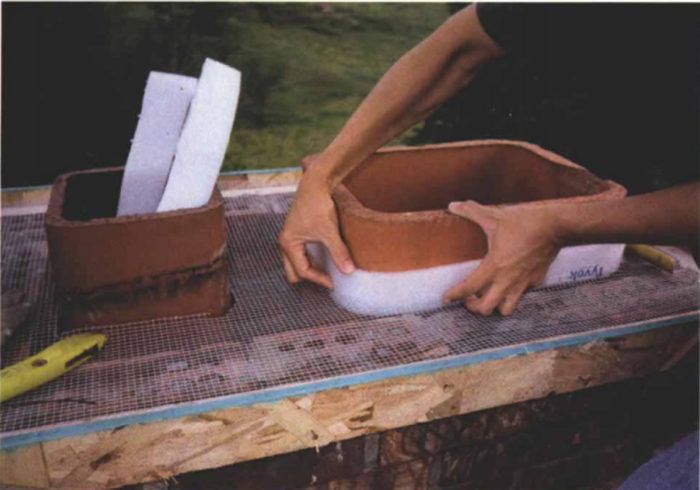

A simple form, wire mesh and rebar make a better pour

To build the cap, I want to contain the perimeter, support the bottom and isolate the flue tiles against thermal expansion. First, I ring the chimney with a frame of 2x lumber. This gives the drip edge a healthy overhang. Strips of OSB give the form a minimum depth of 1 in. I nail the strips to the frame with 6d nails 12 in. o. c. to keep the 2xs from splitting. This form is light but strong enough to contain the little pour. A few small wedges between the frame and the brick level the form at the right height to the chimney.

For more photos and details, click the View PDF button below: