Plastic Tub-Showers

One-piece fixtures are quick to install, but should you buy a gelcoat or an acrylic model?

Synopsis: Plastic tub-shower combinations are typically made from either fiberglass or acrylic. This article explains the difference, with tips on installation and a sidebar on custom-molded inserts that cover up old tubs that are too troublesome to remove.

Any plumber in America contemplating three flights of stairs and a 350-lb. cast-iron bathtub would be happy to give you at least one good reason why someone invented the plastic tub-shower. Until the 1960s, a knee-buckling delivery of a heavy tub to a second- or third-floor bathroom was routine. When the plumber had finished hooking up the tub and shower, a tile installer would complete the job. The result was certainly durable, but the process took time and specialized skills. Plus a strong back.

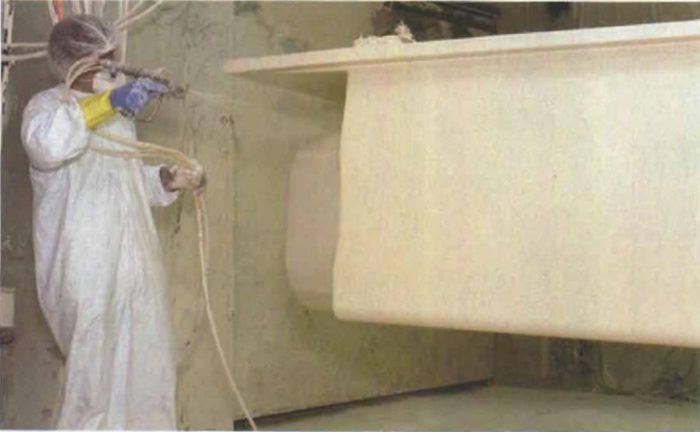

Then came a boom in plastics. Steadily improving polyester resins, and better equipment to combine the material with chopped fiberglass, allowed the mass production of all kinds of things — boats, car fenders and panels for truck trailers and plumbing fixtures. One-piece plastic tub-showers were light and relatively inexpensive, and they could be installed quickly. Later, manufacturers began making combination tub-showers from molded acrylic plastic reinforced with fiberglass.

Combination tub-showers are now made by dozens of companies, large and small, and in a variety of price ranges. The most elaborate models include a half-dozen shower heads, CD players, television screens, steam generators and whirlpool jets (gazing at one of these aquatic entertainment centers at a Chicago trade show earlier this year, a dumbfounded observer wondered aloud, “Why would anyone ever get out of the shower?”). Most tub-showers are more basic than that.

No matter what the brand name or its features, a plastic tub-shower will be either fiberglass-reinforced plastic, what the industry usually calls FRP or gelcoat, or molded acrylic plastic. In addition to one-piece fixtures, limited by their size to new construction, you may also choose a remodeler’s tub-shower that is assembled from three or four separate pieces small enough to be maneuvered through a finished house.

Plumbers may not buy as many Doan’s Pills as they used to, but they are not universal in their praise of either gelcoat or acrylic tub-showers. Although manufacturers disagree, many plumbers don’t think plastic tub-showers will last as long as cast iron and tile. One-piece plastic fixtures come in a few standard sizes that are harder to adapt to odd-size bathrooms. Plastic can be noisy, and it doesn’t retain heat as well as cast iron. Even so, their seamless, no-leak design and advantages in weight and ease of installation have made plastic tub-showers as common as plastic-laminate countertops. And there’s no getting around the lower cost. An acrylic tub-shower can cost about $1,000, rivaling the cost of a traditional installation. But no-frills gelcoat models start at about $200 at big building-supply dealers.

For more photos and details, click the View PDF button below:

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Musings of an Energy Nerd: Toward an Energy-Efficient Home

Anchor Bolt Marker

100-ft. Tape Measure