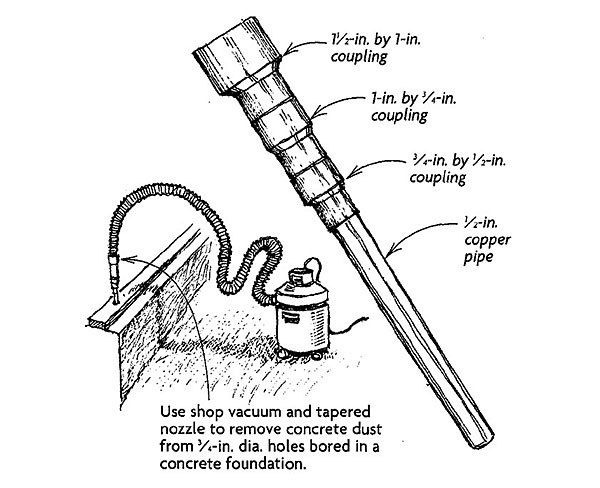

I frequently drill holes in concrete foundations for seismic anchors, such as all-thread bolts. The bolts are bonded to the concrete with epoxy, which means the holes that I drill have to be thoroughly cleaned for the epoxy to get a proper grip. I used to blow the dust out of the holes with compressed air, but that technique makes a mess and poses a danger to lungs and eyes. So I’ve switched to a better method.

As shown in the drawing, I made a simple nozzle out of copper plumbing fittings for my shop vacuum. The series of copper reducers steps down to an 8-in. long piece of 1/2-in. copper pipe, which is small enough in diameter to fit inside the 3/4-in. dia. holes in the concrete. And just for the fun of it, if you like horns, the nozzle sounds pretty good when blown through the 1/2-in. dia. end.

—Randi Dickson, Oakland, CA

Edited and illustrated by Charles Miller

From Fine Homebuilding #120

View Comments

Wow, what a lot of unnecessary work! Blow away the very minimal dust mess and clean the hole with a few bursts of compressed air that might last as much as ten seconds! Better yet, use a wedge anchor which requires no epoxy and no cleaning.

@nailbender123 it would take 10 minutes for me to solder this together, so not really alot of work at all. Blowing the air out with compressed air isn't any faster than vacuuming it out. You may want to polish up on your reading skills. He said he used to use compressed air but found this way better for him. Also since the bolts are seismic anchors you have to use epoxy, anchor bolts don't have the required strength.

Guess what the anchor bolt approvals (whether wedge anchor or epoxy) say about how to clean the holes! Your anchor bolts are the ones that the after-earthquake investigators will write up as “Failure due to Improper installation.”

If you want to get practical about this, stick your suction nozzle in the hole for as long as you want and then put in a compressed air nozzle to see how much dust you’ve left in the hole. This is a tip made in hell.