Block Planes for Carpenters

A veteran carpenter surveys the current offerings and tells how he gets the best performance from his planes.

Synopsis: The author looks at block planes, one of the most versatile hand tools a carpenter or cabinetmaker is likely to use. He examines many of the offerings on the market, with price information as well as pros and cons. A sidebar shows how to sharpen a blade.

When asked if he owned a block plane, a carpenter I know smirked, “Yeah, I’ve got one at the bottom of my toolbox. I use it to open pop bottles.” It’s a common attitude rooted, I think, in carpenters’ frustrations with dull, out-of-whack planes. Most of the carpenters I know haven’t learned how to sharpen and tune a plane, and think it’s a time-consuming, esoteric art.

I have no more time to waste than anybody else. But I use block planes almost every day. I do this because, sharpened and tuned, they’re efficient tools that save me time and produce good work.

Low-angle planes shear end grain

The two main categories of block planes are differentiated by the angle at which the iron (or blade) beds to the plane body. Within each category, planes are further distinguished by whether the throat, the opening in the sole through which shavings pass, is fixed or adjustable.

All the standard-angle planes that I reviewed for this article are bedded at 20° or 21°. A standard-angle block plane does its best work on edge-grain wood (as opposed to end grain), truing extension jambs, removing saw marks or chamfering sharp edges.

Low-angle block planes have a bed angled at about 12°. Their shearing cut was intended to surface end grain, making them great for trimming miters. Low-angle planes also excel at trimming plastic laminates and composite materials such as particleboard and plywood.

Adjustable-throat planes take the finest shavings

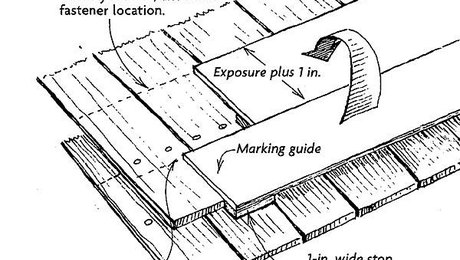

Adjustable-throat planes have a movable plate set into their sole before the throat. A small lever atop the plane cams this plate back and forth, opening and closing the throat. A knurled knob that doubles as a finger rest locks the plate in place.

With the plane iron set to cut deeply, a wide throat allows large, coarse shavings to pass, making for quick but rough work. A narrow throat works with the iron adjusted to take a shallow cut and lets only fine shavings pass. The going is slower, but with a sharp iron, the finished surface can be glassy smooth.

A survey of block planes

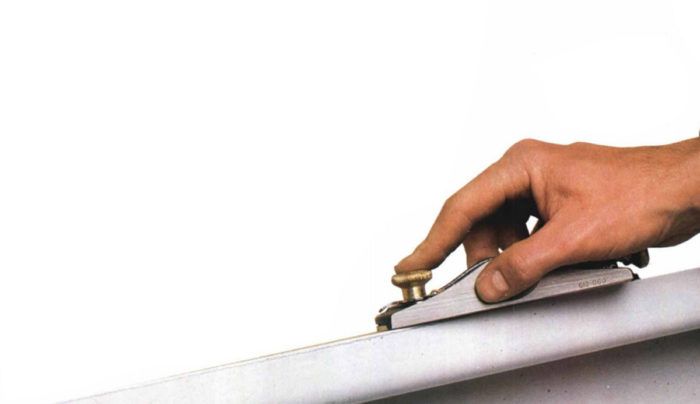

For several months I’ve had the pleasure of trying out different makes of block planes both on the job site and in my shop. I first used each plane right out of the box. Then I checked the soles for flat, the beds for parallel and the irons for square.

After this initial check, I tuned each plane as needed. Then I tested each plane by planing and chamfering long grain and end grain on white pine and white oak. I glued a piece of plastic laminate to high-density particleboard and planed the edge. Finally, I used the planes to chamfer plastic laminate.

For more photos and details, click the View PDF button below:

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Festool Cordless Track Saw (TSC 55 KeB-F)

DEWALT Impact Driver (DCF885)

Not So Big House