A tightly stretched string is one of the most accurate tools available for getting a straight line on a building. Most of the masons and carpenters that I’ve seen wrap their lines around whatever happens to be handy — a scrap of shingle or a rolled-up piece of cardboard. There is a better way.

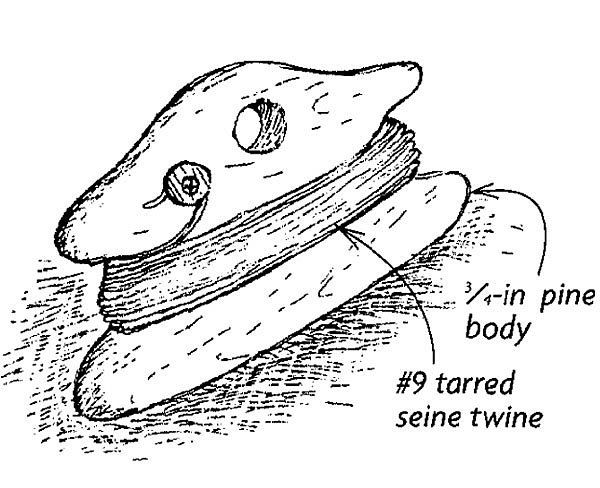

The winder is best made of a wood that is light in weight, such as soft pine, cedar or redwood. Use a bandsaw or a scroll saw to cut out the body of the winder. Then rout all edges with a 1/4-in. roundover bit. Sand to remove splinters, which can snag the line, and then finish with two or three coats of spare varnish.

I use a small, thin washer held in place with a short, round-head screw as a line clip. I dish it with a ball-peen hammer to create a crevice around its perimeter that will secure the line when a turn is taken round it.

The nylon line that I’ve come to love is used as net and seine twine in the commercial-fishing industry. It is commonly tarred, and may be either braided or twisted. The size I use, #9, is roughly 1/16 in. in dia and is very precise. That tar helps the fibers to lie together and resist abrasion. This stuff is far stronger, suppler and tougher than any string I’ve come across.

To use the winder, fill it with line (typically 200 ft.) and use the little clip to hold the free end. To unreel, grasp the hole loosely between thumb and forefinger, allowing the winder to rock back and forth as the line comes off. I usually loop the free end over a nail, tying the other end with an overhand knot, and use the line clip to prevent excess from coming off the winder. If the winder will be used over studs or joists, I often place a small nick along the edge of the first and last framing member with my utility knife. The line will sit in these nicks and not be easily brushed out of position.

You can get a 1-lb. spool of tarred #9 seine twine (2,050 ft. ) for $10 plus shipping from KestralTool (360-468-2103).

Mark White, Birmingham, AL