Framing With Nail Guns

They're as common on job sites as circular saws, but if you're not using your pneumatic nailer properly, maybe you should stick with your hammer.

Synopsis: This article explains how to use pneumatic framing guns safely and efficiently. The authors cover tool maintenance, how to set up compressors, pros and cons of stick and coil nailers, and handling these powerful tools safely.

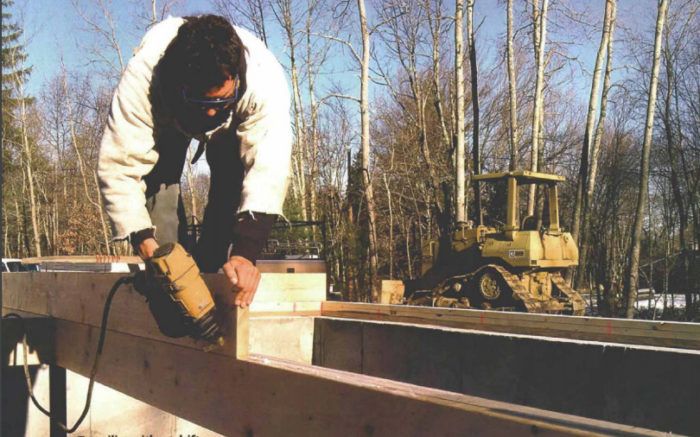

We recently checked in on a friend who was building a 14-ft. by 20-ft. family-room addition. He and his crew were framing with hammers despite having pneumatic nailers right there in the company van. “Too small a project” and “too much trouble to set up” were his responses when we asked why they weren’t using their air nailers.

The next day, we timed how long it takes to set up our compressor, several hoses and two nailers. One crew member set everything up in about same time it took another to drive 20 spikes by hand. This little exercise underscored what we already knew: No job is too small to justify breaking out the guns.

Take care of your guns

While we don’t baby our equipment, nail guns will provide years of service if they are given proper care. Everyone on the crew knows the morning ritual. As each gun is taken out, it is given a quick visual inspection for any safety problems or potential breakdowns, such as sticky safeties, jammed nails or herniated O-rings. Then we put two drops to three drops of pneumatic oil into the air inlet. Sometimes we’ll add an extra drop or two after lunch, if the gun has had a morning of heavy use or if the gun’s operation seems a little sticky.

In the past we’ve tried in-line oilers that attach to the air outlet on the compressor, but we stopped using them. Although they may be fine for some situations, such as in a shop, on a job site they tended to goop up hoses, and they snapped off too easily while we were loading and unloading the compressor.

The oil we use is designed specifically for pneumatic equipment. At first, we used ordinary motor oil in the guns but quickly discovered that the O-rings in the guns deteriorated rapidly and that the cylinder walls turned gummy. Although a little more expensive, pneumatic oil all but eliminated those oil-related problems.

Extension cords for air instead of electricity

Even the best gun won’t work properly without a good air supply, so our compressors get as much attention as our guns and hoses. First, we try to plug the compressor directly into the outlet at the temporary service or power panel. Compressor motors typically require high-amp electricity, and running a compressor through even a short extension cord can cause it to operate sluggishly. Also, the reduced amperage delivered through an extension cord can shorten the life of the compressor motor.

For more photos and information about how to frame with nail guns, click the View PDF button below.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Speed Square

Short Blade Chisel

BOSCH Compact Router (PR20)