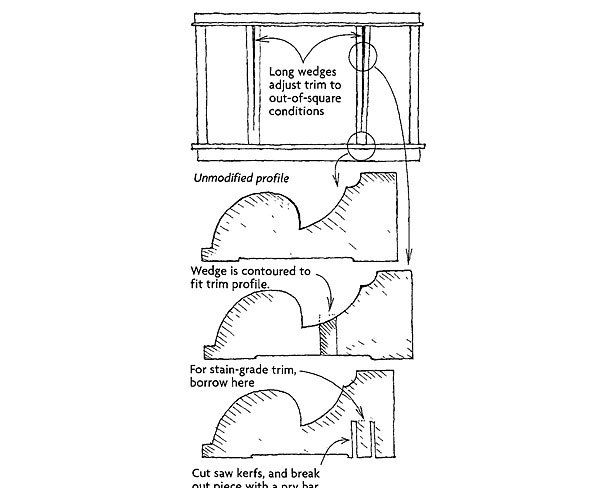

As trim carpenters, we often run into problems when windows or doors are not hung plumb or parallel to adjacent millwork. Take the situation shown in the drawing, for example. Here, out-of-plumb windows are supposed to be trimmed with casings that have even reveals along their edges. In these extreme cases, we often create tapered casings by inserting long wedges into them.

You can add material to almost any casing pattern. Typically, the widest curve or a flat section in the casing is the best place to insert the wedge. We run the casing into the table-saw blade to make the kerf, and then glue in the wedge, letting it stand proud of the profile and then sculpting it to the correct shape with planes and sanding blocks. Incidentally, the new contour sanders are quite useful for this operation.

If the wedged casing runs into a miter, you’ll have to add the same amount to both casings. For stain-grade moldings, you can sometimes “borrow” the necessary material from one of the thicker portions of the casing. As shown in the drawing, cut a couple of kerfs in the backside of the trim piece, and then break out the part between the kerfs with a pry bar. You can fill this excavation with another piece of wood and then use the borrowed piece to craft an invisible wedge.

Gregg Roos, San Francisco, CA