Reinforced Power Cords

Rubber spark-plug boots can help your power tools last longer.

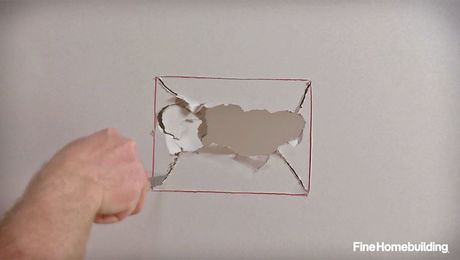

The first thing to fail on every power tool I’ve ever owned is the tapered-rubber strain relief that feeds the power cord into the tool. The large flexible tail breaks off, and eventually, the wires break or short, putting the tool out of service. Official factory replacements are not always stocked locally, and they are often expensive.

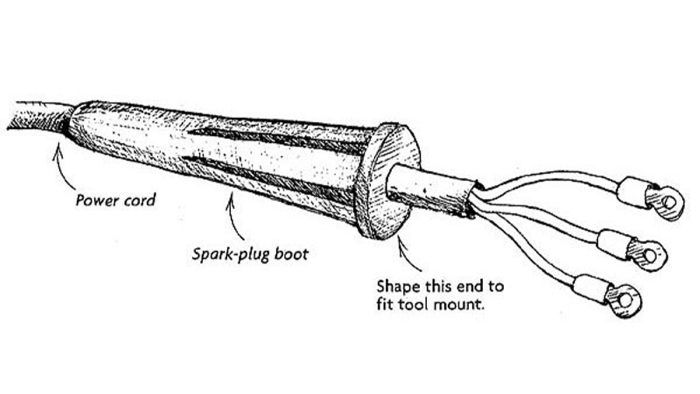

Recently, after doing a major tune-up on my truck, I discovered a handy, inexpensive alternative to the factory replacements — the rubber spark-plug boots used on many modern engines. After the spark-plug wire has been pulled out of the boot, most any power cord can be pushed through the center hole with the help of a little silicone spray.

The flanged end can be carved with a utility knife to fit just about any tool mount. The result is a flexible, durable strain relief that costs nothing. I’ve fitted them with success to my sidewinder, trim, chop, and portable tablesaws. If your car or truck doesn’t use this style spark-plug boot, check at your local auto-repair shop for their throwaways.

— Fred Staal, Isleton, CA. Edited by Charles Miller.

From Fine Homebuilding #128

RELATED STORIES

- Minimize Workbench Cord Tangles

- How to Keep Power Cord Plugs Tight and Dry

- Replace the Cord on a Power Tool

Got a Tip?

Do you have any great tips like this one on reinforcing the cords on your power tools? Share your methods, tricks, and jigs with other readers. Tag them @FineHomebuilding on social, email them to us at [email protected], or upload them to FineHomebuilding.com/reader-tips. We’ll pay for any we publish.

View Comments

Good tip for me! Not because I have trouble with cords breaking but because I change out these ridiculously short (6 - 7 feet) original power cords for more useful lengths - e.g. 12 - 14 feet.