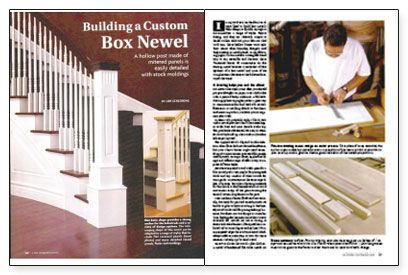

Building a Custom Box Newel

A hollow post made of mitered panels is easily detailed with stock moldings.

Synopsis: A custom stairmaker shows how to build a hollow newel post, with tips on laying out and assembling its many pieces. Sidebars describe the use of a router and jig to cut decorative flutes, how to make a newel cap, and a method of tightening hanger bolts with a long socket wrench.

In my work as a stairbuilder, I’ve always liked to build box newels: Their design is flexible enough to accommodate a range of styles, they’re strong, and they are relatively simple to build. Unlike solid 4×4 posts that are clad with trim, these hollow boxes won’t split their seams when humidity changes, and they’re easier to install plumb. In the following pages, I’ll demonstrate a straightforward way to cut, assemble, and decorate these functional boxes. I’ll concentrate on the starting newel because it embodies all the qualities of a box newel and none of the complications that arise as the balustrade ascends the stairs.

A drawing helps you and the client

No matter what style you’re after, you should put your thoughts on paper, or as I did in this case, a piece of scrap melamine. A full-scale drawing makes a great way to communicate the final look of a newel’s flute sizes or molding details to the client, and more important, it allows you to organize your work.

In terms of a particular style, I like to start with a newel post that’s built like a tree, larger at the base and more slender at the top.The post looks substantial. It’s easy to attain this look by building a box within a box that telescopes upward.

The applied details depend on the situation. Plain flat-sided newels are handsome, but your client’s house might need something a bit more ornate. Recessed flat panels, raised panels, carvings, flutes, applied moldings, and different caps all offer a way to express different styles.

Just about any solid wood works great for a box newel post; I use poplar for paint-grade stock and any number of other woods for stain grade. Construction is the same regardless of species, but when choosing materials for the newel, a chief consideration is wood movement. Keep all the grain running the same direction, lengthwise on the post.

I use medium-density fiberboard occasionally, but only for painted raised panels; it’s harder to glue without resorting to biscuits. Plywood works well for paint-grade applications, but there are two things to consider. One, the lengthwise miter joints that I use to assemble the newels are not as strong as those with solid lumber. (This problem can be solved to some degree with splines.) Two, any exposed edges have to be covered, which always adds an extra step or two. For those reasons, I usually opt for solid wood.

Once I’ve chosen the wood, I plan the box. A newel of unadorned flat sides needs no further preparation now, but a frame of rails and stiles that captures a panel (flat or raised) needs to be assembled before you can cut the miters.

For more photos and details, click the View PDF button below: