Pinning Concrete Forms to Asphalt

Learn how to securely pin concrete forms to asphalt for a durable sidewalk.

Last month, I had a job fixing a deteriorating sidewalk. The new sidewalk was to have a 6-in. tall curb beginning at the edge of some asphalt pavement. I needed to install a 2×6 formboard on a slight angle, and I wanted to leave the forms in place for several days after the pour so that the concrete wouldn’t have to do battle with car tires until it had a chance to cure.

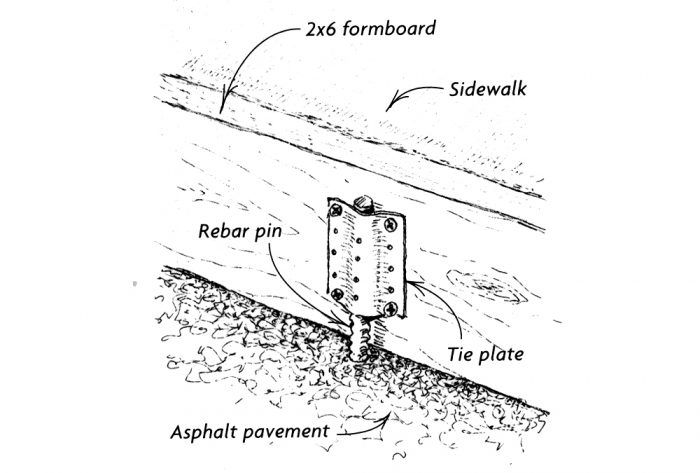

Regular steel form stakes would stand above the forms and be a hazard. And there was no way to drive wooden stakes into the pavement. As shown in the drawing, I used 8-in. lengths of 1/2-in. rebar to solve the problem. First, I drilled 1/2-in.-dia. holes in the pavement, 2-1/2 in. deep and on 4-ft. centers.

Next I cut a bunch of Simpson TP37 tie plates in half. I used my modified 3-1/2-in. by 3-in. plates to attach the formboards to the rebar pins. As I ran the four screws that hold each plate to the board, the tie plates bent around the rebar. I then ground off the top edges of the rebar so that they wouldn’t present a problem to a rubber tire.

A week later, when it was time to strip the forms, I noticed a lot of black tire marks along the formboards. Made me glad the concrete had been protected. After unscrewing the tie plates, I used my Vise-Grip pliers to twist and pull the rebar stakes right out of their holes.

— John La Torre Jr.; Tuolumne, CA

From Fine Homebuilding #134

RELATED STORIES

- Build a Concrete Walkway: Introduction

- Choosing the Right Hand Float for Your Next Concrete Project

- Driveway Material Choices – What’s the Difference?

Got a Tip?

Do you have any great tips like this one on how to pin concrete forms to asphalt? Share your methods, tricks, and jigs with other readers. Tag them @FineHomebuilding on social, email them to us at [email protected], or upload them to FineHomebuilding.com/reader-tips. We’ll pay for any we publish.

View Comments

Depending on what entity owns the asphalt pavement, you might want to consider sealing the holes that you left. In some climates the freeze-thaw cycles will do a number on the edge of the asphalt pavement. Besides, it's simply the right thing to do - you damaged it by drilling the holes, you should make it good.