With Christmas approaching fast, I dreaded the final step of the seven Craftsman-style end tables I was building for family members: sanding and dyeing the 200-odd tiny exposed mahogany pegs that conceal the screws. After bandsawing the pieces from 3/8-in. sq. stock, I contemplated the pile of 3/8-in. sq. by 7/8-in. long rectangles and pondered a way to save myself from sanding them individually.

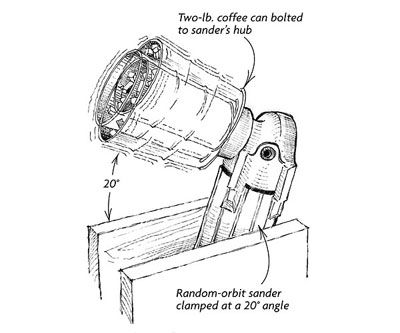

Recalling a childhood lust for my neighbor’s rock tumbler, I disassembled the hook-and-loop sanding pad of my random-orbit sander. In its place, I bolted on an empty 2-lb. coffee can, as shown in the drawing. I poured all the pegs inside and turned on the sander. Voila! I learned that the best mixing/circulation action occurred with the can’s axis at about a 20° angle from the horizontal — about the same angle as a concrete mixer. I clamped the assembly at this angle and let it whir happily away. I thought about adding some bits of sandpaper but didn’t need to.

About a half-hour later, I checked the results: hundreds of perfectly softened Craftsman-style pegs in light mahogany. But how to get them to take on the deep ebony look of their antecedents?

I sawed off the backs of two large indelible black markers, teased out the saturated felt stuffing and put it in the can along with the pegs. Back to whirring for another 20 minutes, at which point I had perfectly black pegs, ready for installation.

Forrest McCanless, Oxford, GA