Survey of Autofeed Screw Guns

A must for high-production, squeak-free floors, these tools help to keep knees and backs pain-free, and the new models don't jam the way the old ones did.

Synopsis: This tool survey describes what autofeed screw guns are, discusses the pros and cons of the different types of fastener collation systems, and compares the features, specifications, and performance of nine different models.

During coffee breaks, the old-timers at my company love to tell us young guys how good we’ve got it, what with all the newfangled air nailers and power tools we get to use, not like when they were starting out, no sir. Mostly they’re full of bull; but when they reminisce about crawling around on their hands and knees nailing down subfloors, I’m grateful to be from generation X.

I work for a company that does high-end production framing, and we’ve been using autofeed screw guns to anchor subflooring for years. Although we could get the job done a bit faster using air nailers, experience has taught us that used in combination with adhesive, screws are the key to a no-squeak subfloor. Figuring an average cost of 3¢ a piece for the collated (2-in. yellow zinc) fasteners we use for subflooring, we’ve decided that the autofeed screw guns more than pay for themselves by reducing warranty costs and callbacks.

In principle, an autofeed system is simply a screw gun combined with a mechanism that feeds a continuous supply of screws to the drive bit. A fellow gen-Xer would say subflooring is the tool’s “killer app,” but outdoor decks are another popular application. Autofeed screw guns are also used for drywall, metal framing and tile roofing.

For the past few years, our company has been using a QD200 autofeed system that was sold by Quik Drive but manufactured by Holz-Her of Germany. That system is no longer available; and because our guns are getting more than a bit long in the tooth, I was excited when the editors of Fine Homebuilding asked me to evaluate the current crop of autofeed screw guns.

Fastening subfloor to compare these tools

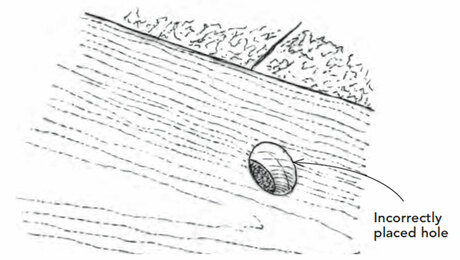

My goal was to assess each tool’s suitability for subflooring work and to offer some perspective on strong and weak points of each tool. For this test, I drove a minimum of 300 #8 by 2-in. screws through each tool. Of those 300 screws, at least 200 were used on our job sites to fasten 3⁄4-in. oriented strand board subflooring to I-joists. To evaluate each tool’s ability to penetrate solid wood, the remaining screws were driven directly into solid wood. To give general contractors and deck builders more to go on, I also used each tool to drive a bunch of 2 1⁄2-in. deck screws into pressure-treated lumber.

I admit that this limited test didn’t tell me much about the long-term reliability of a tool. It was enough, however, to draw some conclusions about out-of-the-box quality, ergonomics, reliability and ease of use. My favorite tool might not be the best choice for you, however. Autofeed fastening systems are similar to air nailers and powder-actuated fasteners, in the sense that the fasteners are almost as important as the tools themselves. Whichever tool you choose, you’ll want to make sure that fasteners, parts and service are readily available in your area.

For more photos and details, click the View PDF button below:

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Code Check 10th Edition: An Illustrated Guide to Building a Safe House

DEWALT 2 1⁄4-hp Router Combo Kit (DW618PK)

Paslode Cordless Finish Nailer (IM250A)